Researchers at Delft University have shown that placing certain types of bacteria on flat sheets of graphene oxide can turn it into a reduced version of the compound (rGO) by pulling oxygen atoms off the material as they metabolize. This turns the popular process of GO reduction, normally done with chemicals or high heat, into a much cheaper, more environmentally friendly process.

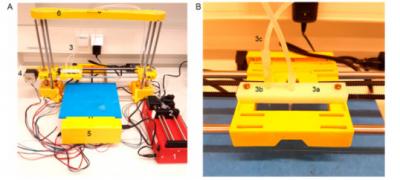

While the traditional method of reducing graphene with heat or chemicals is still more effective, the bacterial method could be very useful in the production of precise, small-scale graphene structures such as those produced with a 3D printer. In this work, the researchers document how they modified a $300 CoLiDo 3D printer by replacing the extruder with a pipet tip and tubing system. This alteration allows the liquid biological ink (‘bioink’) to be transported under ambient temperatures that are amenable to microbes, rather than the elevated temperatures that are applied to melt plastic filament, the team explains.

The bioink was created by combining live E. coli bacteria with an alginate gel that, when extruded onto a calcium ion surface, solidified to form a firm scaffold. The TU Delft researchers’ ultimate goal isn’t to 3D print E. coli their initial work has so far only been to show that bacteria can be successfully 3D printed. The real goal is to 3D print a type of graphene oxide-reducing bacteria called Shewanella oneidensis onto 2D sheets of the material in specific patterns that will allow the researchers to carefully tailor its properties.

For example, it may eventually be possible to carve tiny conductive wires into the surface of the graphene oxide to make certain parts of it conductive while the rest remains non-conductive. But the team is not there yet; the key now is finding a way to print the bacteria with enough growth medium that it lives long enough to reduce the graphene oxide without losing its precise shape a difficult balance to reach. The team does have big plans for when they reach that goal - they intend to find out if it’s possible to use similar technology to modify substances found in lunar dust, which could eventually allow to 3D print electronic devices in space. Currently, they are working with bacteria to try to turn silica and iron oxide from replicated lunar soil into silicon and iron.