Graphene water treatment company raises £4 million

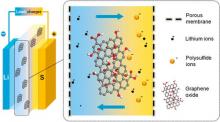

Arvia, a UK-based water and wastewater treatment company, has secured £4 million in its latest round of investment funding. The company developed its own graphene-based proprietary material called Nyex which removes organics, contaminants and micro-pollutants from wastewater and is regenerated in-situ in the novel organics destruction cell (ODC) process. The technology was spun-out of Manchester University’s School of Chemical Engineering.

Arvia’s modular treatment units can remove and oxidise low, trace toxic and problematic pollutants. The company says it has numerous test units to deploy into the market and are looking for early adopters to collaborate with Arvia in applying this technology.