Graphene-based flat pack batteries offer improved performance

Researchers at the University of Wollongong's Institute for Superconducting and Electronic Materials designed a graphene-based flexible, foldable, and lightweight energy storage device for use in next-gen wearable technology and also as a potential device for medical implants, like pacemakers.

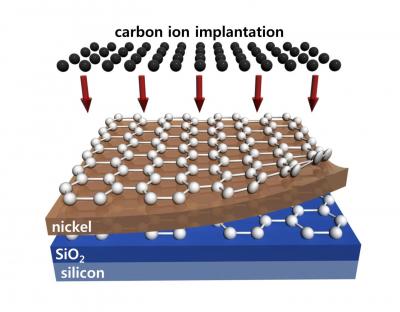

The scientists devised a 3D structure: liquid graphene was mixed with a polymer and the combination was then solidified to form the carbon nanotubes. The resulting structure was made-up of three parts: graphene, a conductive polymer, and carbon nanotubes. These three parts take the form of single atom-thick networks, resembling carbon formed cylinders. The novel design is efficient because by separating out the layers of carbon, researchers are able to use both surfaces in the structure for charge accumulation. The scientists expect this design to lead to ultra-fast and efficient battery devices.