Exeter's GrapheExeter material to enable meter-sized flexible displays

Researchers at Exeter have devised a graphene composite (GraphExeter) that is highly conducting, and now they demonstrate the first prototype of the material in an electroluminescent device, showing its feasibility for luminescent textiles and flexible displays.

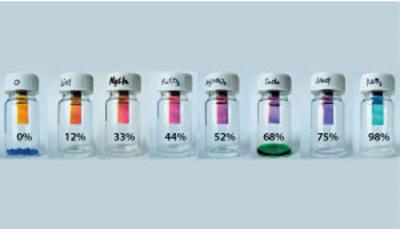

The high conductivity of GraphExeter can introduce many improvements to flexible displays. Large screens using existing materials fade to a darker region in the middle due to the sheet resistance. This places a practical limitation in the range of square centimetres on how large the screen can be. The extremely low sheet resistance of GraphExeter - less than 8Ω/⡠compared with 1000Ω/⡠for pristine single layer graphene and 850Ω/⡠for the more commonly used PEDOT/PSS means that screens several square metres in size are feasible.