Garmor, the University of Central Florida spin-off formed to develop a new graphene oxide flakes production process, has developed graphene oxide-based coatings useful for limiting UV radiation damage to sensors and polymers. Garmor’s transparent GO-films are reprtedly derived from a commercially-viable and scalable process that can be readily implemented with minimal constraints.

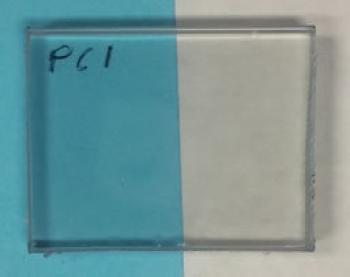

Four layers of GO coating on polycarbonate

Four layers of GO coating on polycarbonate

One of the most promising applications for this material is for coating plastics and polymers susceptible to UV degradation. While a single-layer GO-film maintains greater than 96% transparency in the visible spectrum, the GO-film significantly reduces the transmission of UV radiation below 360nm. Such a film could prove quite beneficial for coating a variety of products including polycarbonate automotive products, photovoltaic panels, and skylights. Transparent GO-films have great potential for use as sensors thanks, in part, to its low resistivity and UV protective coating application. Applications include use as a defogger element, integrated antenna, UV protective element in a windshield, and visor use in a disposable sensor.

Garmor states that it delivers high-quality graphene at affordable prices, and also provides unique solutions for using graphene oxide in select applications. The use of GO-films is meant to extend the lifetime of a variety of consumer products and minimize maintenance costs and warranty replacements. In addition, this new material could prove quite attractive for developing low-cost and potentially even disposable sensors.