Graphene is a one-atom-thick sheet of carbon atoms arranged in a honeycomb-like pattern. Graphene is considered to be the world's thinnest, strongest and most conductive material - of both electricity and heat. All of these properties are exciting researchers and businesses around the world - as graphene has the potential to revolutionize entire industries - in the fields of electricity, conductivity, energy generation, batteries, sensors and more.

Mechanical strength

Graphene is the world's strongest material, and can be used to enhance the strength of other materials. Dozens of researchers have demonstrated that adding even a trace amount of graphene to plastics, metals or other materials can make these materials much stronger - or lighter (as you can use a smaller amount of material to achieve the same strength).

Such graphene-enhanced composite materials can find uses in aerospace, building materials, mobile devices, and many other applications.

Thermal applications

Graphene is the most heat conductive found to date. As graphene is also strong and light, it means that it is a great material for making heat-spreading solutions, such as heat sinks or heat dissipation films. This could be useful in both microelectronics (for example to make LED lighting more efficient and longer lasting) and also in larger applications - for example thermal foils for mobile devices. Huawei's latest smartphones, for example, have adopted graphene-based thermal films.

Energy storage

Since graphene is the world's thinnest material, it also extremely high surface-area to volume ratio. This makes graphene a very promising material for use in batteries and supercapacitors. Graphene may enable batteries and supercapacitors (and even fuel-cells) that can store more energy - and charge faster, too.

The advantages of graphene batteries

The advantages of graphene batteries

Coatings ,sensors, electronics and more

Graphene has a lot of promise for additional applications: anti-corrosion coatings and paints, efficient and precise sensors, faster and efficient electronics, flexible displays, efficient solar panels, faster DNA sequencing, drug delivery, and more.

Graphene is such a great and basic building block that it seems that any industry can benefit from this new material. Time will tell where graphene will indeed make an impact - or whether other new materials will be more suitable.

The latest Graphene Application news:

First Graphene announces low-cost, high-performing graphene-based electrocatalysts

First Graphene has developed a low-cost, high-performing graphene-based electrocatalyst that targets the rapidly growing production of ‘green hydrogen’ by water electrolysis. Electrocatalysts are used to produce ‘green hydrogen’, but currently require high-cost rare metals such as iridium and ruthenium which can drive up operating costs. First Graphene’s solution uses its PureGRAPH® technology to produce higher-performing, affordable electrocatalysts.

First Graphene has completed a 12-month project in the United Kingdom to develop low-cost, high-performing electrocatalysts for hydrogen production.

Levidian unveils graphene-enhanced prototype truck tire

Levidian has unveiled its first prototype truck tire, combining graphene with carbon black in a new tread formulation. Launched this week at the Tire Technology Expo in Hannover, the graphene-enhanced natural rubber and butadiene rubber tire tread compound, typically used in commercial vehicle tires, has been shown to deliver significant improvements in the mechanical and dynamic properties of the tire.

Independent testing by the Tun Abdul Razak Research Centre (TARRC) has reportedly shown that the addition of Levidian’s 'net zero graphene' can deliver a reduction in rolling resistance of around 23%. Initial results have also indicated potential for reduced compound density that could allow for lighter tires overall. It was said that overall, this could deliver substantial improvements in fuel efficiency of 3-4%.

Researchers develop approach for creating tight arrangement of bilayer alkali metals between graphene layers for improved batteries

Researchers at AIST, Osaka University, Tokyo Polytechnic University, Kyushu University, and National Tsing Hua University, have developed a technique to insert alkali metals (AMs) into the interlayers of graphene. They them used low-voltage scanning transmission electron microscopy (LV-STEM) to visualize the atomic structure of the intercalated AMs (potassium, rubidium, and cesium) in the bilayer graphene (BLG). The team's findings revealed that the intercalated AMs adopt bilayer structures with hcp stacking, and specifically a C6M2C6 composition.

The performance of rechargeable batteries is a key factor influencing the driving distance of electric vehicles and the usage time of smartphones. Improving the performance of these electronic devices is possible if rechargeable batteries can accumulate greater electrical capacities. Graphite, the electrode material used in batteries, is composed of multilayers of graphene, with alkali metals placed between the layers to facilitate the flow of electrons during charging and discharging. Achieving a high density of alkali metals storage between graphene layers could increase the electric capacity.

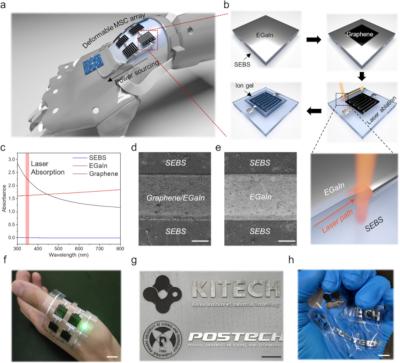

Researchers develop deformable graphene-based liquid metal micro-supercapacitors

Researchers from Pohang University of Science and Technology (POSTECH), Korea Institute of Industrial Technology and Konkuk University have fabricated highly deformable graphene-based micro supercapacitors (MSCs) using liquid metal current collectors on an elastic polymer substrate.

a Illustration of an integrated system comprising soft-electronics and deformable energy storage component. b The fabrication process of EGaIn-based MSC. c UV-vis spectra of SEBS, EGaIn, and graphene. FE-SEM images of laser ablated d Graphene/EGaIn and e EGaIn (Scale bar = 200 µm). Photographs of f institute logos, g deformed logos, and h an LED connected to the MSC circuit (Scale bar = 1 cm). (Image from npj Flexible Electronics)

The team used eutectic gallium-indium (EGaIn), a liquid metal alloy, as the current collector since a deformable current collector is needed in order to create a deformable MSC. Commonly used current collectors made of brittle materials like gold (Au) are not suitable in this case, so the team turned to 'liquid metal' that inherently possesses the properties of a liquid and metallic conductivity.

Lyten announces manufacturing milestone - producing Lithium-sulfur batteries at greater than 90% yield

Lyten recently announced it is consistently surpassing 90 percent yield from its automated battery production line, confirming the manufacturability of its lithium-sulfur battery utilizing a sulfur cathode and lithium metal anode.

The lithium-sulfur manufacturing performance has been achieved utilizing standard lithium-ion manufacturing equipment and processes. The conversion of lithium-ion equipment to produce lithium-sulfur batteries in Lyten’s pilot facility required 6 weeks and less than 2% of the total capital cost. This confirms Lyten’s ability to rapidly scale by converting existing Li-ion gigafactories to lithium-sulfur with minimal cost and time.

Archer Materials miniaturizes biochip gFET chip design

Archer Materials has designed a miniaturized version of its Biochip graphene field effect transistor ("gFET") chip for fabrication at a commercial foundry.

The Archer Biochip contains a sensing region of which the gFET is the core component. Each gFET chip contains multiple gFETs, each of which is a transistor, which acts as a sensor. Archer has miniaturized the total chip size by redesigning the layout of the circuits creating these gFET transistors. The new miniaturized design has been sent to a foundry partner for a whole-wafer fabrication of reduced size gFET chips, which Archer intends to integrate with other parts of the Biochip technology.

Solidion Technology begins trading on NASDAQ, aims to advance eVTOL aircraft with graphene-enhanced batteries

Solidion Technology, an advanced battery technology solutions developer, began trading on NASDAQ (ticker symbol “STI”) on February 5, 2024. Solidion is the merged entity between Honeycomb Battery Company (HBC, Dayton, Ohio) and Nubia Brand International Co., a special purpose acquisition company (SPAC), based in Dallas, Texas.

Some see electric vertical takeoff and landing (eVTOL) aircraft as the next urban transportation technology breakthrough. At the heart of an eVTOL aircraft is a heavy battery pack. The amount of energy that can be stored in a battery pack with a reduced mass must be significantly increased before the eVTOL industry can literally take off. It is estimated that eVTOL aircraft needs a battery system with a gravimetric energy density > 400 Wh/kg. For an air taxi to carry more passengers, a battery cell energy density higher than 450 or even 500 Wh/kg will be required.

ColossusTex launches a new graphene yarn

India-based textile supply chain company ColossusTex has unveiled a new graphene yarn.

The company states that its new graphene yarn boasts a myriad of benefits that set it apart from traditional yarns, like an antibacterial rate of 99%, odor elimination and significant reduction of the chance of skin diseases. Also, the incorporation of far-infrared health care technology promotes microcirculation on the body surface, enhances blood circulation, and boosts cellular metabolism.

New project will focus on graphene 'lab on a chip' medical diagnostic technology for rapid detection of infections

Researchers at the Liverpool School of Tropical Medicine (LSTM) will collaborate with ProMake, a material science and diagnostic company, as part of Innovate UK's Accelerated Knowledge Transfer Scheme. The new project will investigate how graphene technology could be utilized to rapidly detect infection and act as the basis for new medical diagnostics.

ProMake has developed a novel device prototype, the 'BioPod', a hand-held point-of-care diagnostic containing the graphene lab-on-a-chip (LOC) electrode. The LOC uses functionalized graphene, a super-strong and thin material laced with specific receptors, to detect a wide range of pathogens. The aim is to use the BioPod in the same way as lateral flow tests (LFTs), to test for COVID-19 and other pathogens. However, unlike LFTs, which provide quick results but with less accuracy than tests processed in the lab, the BioPod's advanced technology has the potential to be more accurate and easier to interpret.

Directa Plus and Chronos Corps launch high-tech bag with graphene and fingerprint opening

Directa Plus and Chronos Corps have launched a high-tech bag with graphene and fingerprint opening.

Launched just in time for Fashion Week, this collaboration blends fashion and technology, showcasing the versatility of Directa Plus materials. Crafted with Coating G+®, a special water-based coating enriched with Graphene Plus, this bag not only boasts a sleek design but also offers unmatched functionality, including antimicrobial protection (antibacterial and antiviral), UV resistance, abrasion resistance, antistatic properties and thermal conductivity. It also has advanced fingerprint recognition for secure access.

Pagination

- Previous page

- Page 2

- Next page