What is ink?

Ink is a mixture of ingredients formulated to create a substance containing pigments or dyes that is used to color a surface. Inks usually come in liquid or paste form, and can be divided into four general classes of aqueous, liquid, paste and powder.

Most inks contain four basic components: colorants (that grant color and opacity), binders (mostly resins that serve to hold together other components), additives (like wax or chalk, used to grant specific traits) and carrier substances (like oils, which allow the ink to flow, spread and transfer). The ink industry is valued at over $10 billion as ink is somewhat ubiquitous and found in writing paraphernalia and print (including newspapers and books).

What are the common types of ink?

Inks are roughly divided into printing inks and writing inks. Writing inks, like the ones found in pens, started out using water-based dye systems and evolved into paste oil-based dyes that improve ink flow, and are generally more non smearing and quicker to dry than water-based systems.

Printing inks are categorized in two groups: inks for conventional printing (using a mechanical plate that transfers an image to the printed object) and inks for non-impact printing like ink-jet and electrophotographic technologies.

Conductive inks

Conductive inks contain components that provide the function of conductivity. Such components may be comprised of silver, carbon, graphite, or other precious metal coated base material. Common conductive inks can be classified into three categories: noble metals, conductive polymers, and carbon nanomaterials. Conductive inks can be used in various ways, including screen printing, flexographic or rotogravure, spray, dip, and more. A selection of conductive inks are offered on the market, to meet the demands of many applications: electronics, sensors, antennae, touch screens, printed heaters and more.

What is graphene?

Graphene is the thinnest and strongest material known to man. It is also an excellent electrical and heat conductor that has unique optical properties. Graphene is a 2D material made of carbon atoms, arranged in a honeycomb lattice. Its myriad qualities make graphene worthy of the title “wonder material”, with endless potential for all sorts of applications from membranes to electronics.

Graphene inks

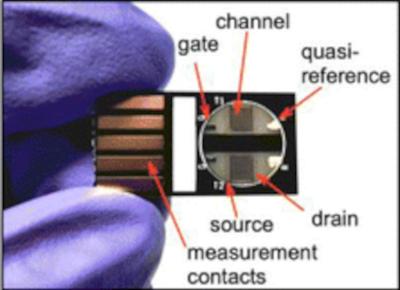

Carbon nanomaterials offer many possibilities for printed and flexible electronics. The electrical properties of carbon nanotubes and graphene are particularly promising, and have been exploited in a number of applications from thin-film transistors (TFTs) and electrochemical sensors to supercapacitors and photovoltaics. Due to its high charge carrier mobility, superlative thermal and chemical stability and intrinsic flexibility, graphene has been demonstrated for a number of applications in printed electronics including chemical and thermal sensors, supercapacitors and more.

Graphene inks expand the possibilities for applications such as printed electronics, packaging and electronics, but often need to be specially formulated or adjusted for specific uses, like unique substrates or processing/printing methods (rotogravure, flexo, or screen printing processes etc.) as demands vary for the different uses. Screen printing, for example, usually requires optimal coverage capability while flexographic printing warrants rapid drying.

The graphene inks market

The graphene market can be a confusing one. While there are some companies that sell graphene inks, like Haydale and Vorbeck Materials, many other companies are involved in different aspects of the market. For example, Angstron Materials do not sell graphene inks but offer graphene nanoplatelets (GNPs) that can be dispersed in solvent to create graphene ink of sorts. Other companies are in various stages of developing graphene inks and accessory products. Graphene 3D printing can be done by using a liquid similar to ink, yet it is different than the inks that are used for other applications.

If you’re interested in graphene inks and wish to find the one suitable for your needs, contact Graphene-info - the graphene experts. We use our unique market familiarity and understanding to assist you in finding exactly what you are looking for.

Further reading

Latest Graphene Ink news