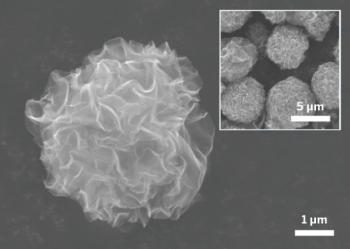

Korean Scientist at the university of Yonsei in Seoul and the Korean Institute of Ceramic Engineering & Technology designed round graphene microparticles by spraying graphene oxide droplets into a hot solvent. This technique could pose a versatile and simple approach to making electrode materials for batteries and supercapacitors with improved energy and power densities.

The researchers' particles comprise of graphene nanosheets radiating out from the center, an arrangement that increases the exposed surface area of the graphene and creates open nanochannels that can enhance charge transfer. The work was doen by passing an aqueous suspension of graphene oxide flakes through an ultrasonic nozzle, which uses sound waves to break the suspension into microdroplets. The scientists then sprayed the droplets downward into a 160° C mixture of organic solvent and ascorbic acid, a reducing agent. The hot mixture allows the graphene oxide to reduce to graphene sheets that cluster together. The water in the droplets evaporates and escapes toward the surface, which causes the unique arrangement of the nanosheets.

To test the graphene-only spheres, the researchers fabricated 1- by 1-cm electrodes, and immersed the electrode and another made from unassembled graphene sheets in a sulfuric acid electrolyte. The microsphere electrode had a capacitance of 151 farad per gram compared with 118 F/g for the plain graphene electrode, demonstrating that the 3D structure of the particles improved performance.

The capacitance of the pompom-like graphene electrodes is similar to that of other electrodes made with 3D graphene materials, but the novel technique makes this work unique and important because it is direct, simple, and quite easy to scale up for industrial applications,according to the scientists. Another key advantage is that the method allows functional nanoparticles to be trapped directly into the microspheres to form nanocomposites.