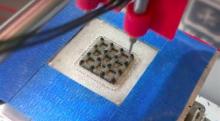

Researchers at Kansas State University, University of Buffalo and the State University of New York have designed a new technique for 3D printing graphene aerogels with complex microstructures. The technique combines drop-on-demand 3D printing with freeze casting.

Aerogels are light and spongy materials that can be used as both thermal and optical insulators and can potentially be used as batteries and catalysts within electronic components. Recent years have brought about methods in which aerogels can be produced with certain 3D printers. The scientists have now developed a new 3D printing technique for producing graphene aerogels, which they hope will open up new uses for the material.

The 3D printed graphene aerogel was finally freeze-dried in liquid nitrogen to get rid of all of the water deposited by the second printer nozzle, before being thermally reduced to graphene. The scientists were able to 3D print aerogels with densities ranging from 0.5 to 10mg/cm3, each with good electrical conductivity and high compressibility.