Graphene and batteries

Graphene, a sheet of carbon atoms bound together in a honeycomb lattice pattern, is hugely recognized as a “wonder material†due to the myriad of astonishing attributes it holds. It is a potent conductor of electrical and thermal energy, extremely lightweight chemically inert, and flexible with a large surface area. It is also considered eco-friendly and sustainable, with unlimited possibilities for numerous applications.

The advantages of graphene batteries

The advantages of graphene batteries

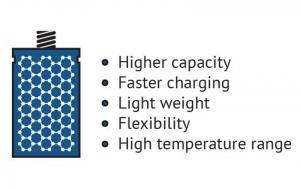

In the field of batteries, conventional battery electrode materials (and prospective ones) are significantly improved when enhanced with graphene. A graphene battery can be light, durable and suitable for high capacity energy storage, as well as shorten charging times. It will extend the battery’s life, which is negatively linked to the amount of carbon that is coated on the material or added to electrodes to achieve conductivity, and graphene adds conductivity without requiring the amounts of carbon that are used in conventional batteries.

Graphene can improve such battery attributes as energy density and form in various ways. Li-ion batteries (and other types of rechargeable batteries) can be enhanced by introducing graphene to the battery’s anode and capitalizing on the material’s conductivity and large surface area traits to achieve morphological optimization and performance.

It has also been discovered that creating hybrid materials can also be useful for achieving battery enhancement. A hybrid of Vanadium Oxide (VO2) and graphene, for example, can be used on Li-ion cathodes and grant quick charge and discharge as well as large charge cycle durability. In this case, VO2 offers high energy capacity but poor electrical conductivity, which can be solved by using graphene as a sort of a structural “backbone†on which to attach VO2 - creating a hybrid material that has both heightened capacity and excellent conductivity.

Another example is LFP (Lithium Iron Phosphate) batteries, that is a kind of rechargeable Li-ion battery. It has a lower energy density than other Li-ion batteries but a higher power density (an indicator of of the rate at which energy can be supplied by the battery). Enhancing LFP cathodes with graphene allowed the batteries to be lightweight, charge much faster than Li-ion batteries and have a greater capacity than conventional LFP batteries.

In addition to revolutionizing the battery market, combined use of graphene batteries and graphene supercapacitors could yield amazing results, like the noted concept of improving the electric car’s driving range and efficiency. While graphene batteries have not yet reached widespread commercialization, battery breakthroughs are being reported around the world.

Battery basics

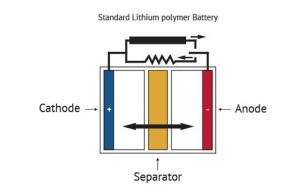

Batteries serve as a mobile source of power, allowing electricity-operated devices to work without being directly plugged into an outlet. While many types of batteries exist, the basic concept by which they function remains similar: one or more electrochemical cells convert stored chemical energy into electrical energy. A battery is usually made of a metal or plastic casing, containing a positive terminal (an anode), a negative terminal (a cathode) and electrolytes that allow ions to move between them. A separator (a permeable polymeric membrane) creates a barrier between the anode and cathode to prevent electrical short circuits while also allowing the transport of ionic charge carriers that are needed to close the circuit during the passage of current. Finally, a collector is used to conduct the charge outside the battery, through the connected device.

When the circuit between the two terminals is completed, the battery produces electricity through a series of reactions. The anode experiences an oxidation reaction in which two or more ions from the electrolyte combine with the anode to produce a compound, releasing electrons. At the same time, the cathode goes through a reduction reaction in which the cathode substance, ions and free electrons combine into compounds. Simply put, the anode reaction produces electrons while the reaction in the cathode absorbs them and from that process electricity is produced. The battery will continue to produce electricity until electrodes run out of necessary substance for creation of reactions.

Battery types and characteristics

Batteries are divided into two main types: primary and secondary. Primary batteries (disposable), are used once and rendered useless as the electrode materials in them irreversibly change during charging. Common examples are the zinc-carbon battery as well as the alkaline battery used in toys, flashlights and a multitude of portable devices. Secondary batteries (rechargeable), can be discharged and recharged multiple times as the original composition of the electrodes is able to regain functionality. Examples include lead-acid batteries used in vehicles and lithium-ion batteries used for portable electronics.

Batteries come in various shapes and sizes for countless different purposes. Different kinds of batteries display varied advantages and disadvantages. Nickel-Cadmium (NiCd) batteries are relatively low in energy density and are used where long life, high discharge rate and economical price are key. They can be found in video cameras and power tools, among other uses. NiCd batteries contain toxic metals and are environmentally unfriendly. Nickel-Metal hydride batteries have a higher energy density than NiCd ones, but also a shorter cycle-life. Applications include mobile phones and laptops. Lead-Acid batteries are heavy and play an important role in large power applications, where weight is not of the essence but economic price is. They are prevalent in uses like hospital equipment and emergency lighting.

Lithium-Ion (Li-ion) batteries are used where high-energy and minimal weight are important, but the technology is fragile and a protection circuit is required to assure safety. Applications include cell phones and various kinds of computers. Lithium Ion Polymer (Li-ion polymer) batteries are mostly found in mobile phones. They are lightweight and enjoy a slimmer form than that of Li-ion batteries. They are also usually safer and have longer lives. However, they seem to be less prevalent since Li-ion batteries are cheaper to manufacture and have higher energy density.

Batteries and supercapacitors

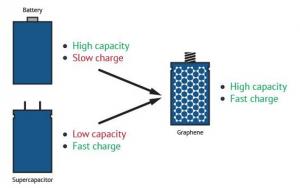

While there are certain types of batteries that are able to store a large amount of energy, they are very large, heavy and release energy slowly. Capacitors, on the other hand, are able to charge and discharge quickly but hold much less energy than a battery. The use of graphene in this area, though, presents exciting new possibilities for energy storage, with high charge and discharge rates and even economical affordability. Graphene-improved performance thereby blurs the conventional line of distinction between supercapacitors and batteries.

Graphene batteries combine the advantages of both batteries and supercapacitors

Graphene batteries combine the advantages of both batteries and supercapacitors

Graphene-enhanced batteries are almost here

Graphene-based batteries have exciting potential and while they are not yet fully commercially available yet, R&D is intensive and will hopefully yield results in the future. Companies all over the world (including Samsung, Huawei, and others) are developing different types of graphene-enhanced batteries, some of which are now entering the market. The main applications are in electric vehicles and mobile devices.

Some batteries use graphene in peripheral ways - not in the battery chemistry. For example in 2016, Huawei unveiled a new graphene-enhanced Li-Ion battery that uses graphene to remain functional at higher temperature (60° degrees as opposed to the existing 50° limit) and offer a double the operation time. Graphene is used in this battery for better heat dissipation - it reduces battery's operating temperature by 5 degrees.

Further reading

- Introduction to graphene

- Graphene Supercapacitors

- How to invest in the graphene revolution

- The Graphene Handbook, our very own guide to the graphene market

- Graphene-Info's graphene batteries market report

- Graphene supercapacitors market report

The latest graphene batteries news:

Researchers use self-organized crack-free nanocellular graphene film to enhance sodium ion batteries

Researchers from Tohoku University, Tianjin University of Technology, Pohang University of Science and Technology and Johns Hopkins University recently designed a nanocellular graphene (NCG) film through the self-organization of carbon atoms using liquid metal dealloying and employing a defect-free amorphous precursor.

The flexible freestanding nanocellular graphene film. Image credit: Advanced Materials

Nanocellular graphene is a specialized form of graphene that achieves a large specific surface area by stacking multiple layers of graphene and controlling its internal structure with a nanoscale cellular morphology. NCG is attractive thanks to its potential to improve the performance of electronic devices, energy devices and sensors. However, its development has been hindered by defects that occur during the manufacturing process. Cracks often appear when forming NCG, and scientists are looking for new processing technologies that can fabricate homogeneous, crack-free and seamless NCGs at appropriate scales.

GMG secures funding to build graphene aluminum ion battery pilot plant

Graphene Manufacturing Group (GMG) has secured Queensland government backing for a proposed automated battery pilot plant for the manufacture of GMG’s Graphene Aluminum Ion Battery. The Company signed a Queensland Critical Minerals and Battery Technology Fund Agreement with the state for a grant of AUD$2 million (almost USD$1,300,000).

GMG is using graphene to produce aluminium-ion batteries utilizing a patent-pending surface perforation technology developed by the University of Queensland. GMG said the grant was for the payment of 50 percent of the capital cost of GMG’s proposed pilot plant, up to a maximum of $2 million.

Graphene Manufacturing Group secures funding for graphene aluminium ion battery pilot plant

Graphene Manufacturing Group (GMG) has been awarded a AU$2 million (over USD$1,300,000) grant by the Queensland Government to support the development of an automated battery pilot plant for the Company's graphene aluminium ion battery.

The funding aims to bolster the local critical minerals and battery technology industries, contribute to economic growth, and is expected to create 12 new jobs. The grant represents half of the capital costs for the plant, which will be housed within GMG’s existing facility, contingent upon GMG’s final investment decision.

Researchers develop approach for creating tight arrangement of bilayer alkali metals between graphene layers for improved batteries

Researchers at AIST, Osaka University, Tokyo Polytechnic University, Kyushu University, and National Tsing Hua University, have developed a technique to insert alkali metals (AMs) into the interlayers of graphene. They them used low-voltage scanning transmission electron microscopy (LV-STEM) to visualize the atomic structure of the intercalated AMs (potassium, rubidium, and cesium) in the bilayer graphene (BLG). The team's findings revealed that the intercalated AMs adopt bilayer structures with hcp stacking, and specifically a C6M2C6 composition.

The performance of rechargeable batteries is a key factor influencing the driving distance of electric vehicles and the usage time of smartphones. Improving the performance of these electronic devices is possible if rechargeable batteries can accumulate greater electrical capacities. Graphite, the electrode material used in batteries, is composed of multilayers of graphene, with alkali metals placed between the layers to facilitate the flow of electrons during charging and discharging. Achieving a high density of alkali metals storage between graphene layers could increase the electric capacity.

Lyten announces manufacturing milestone - producing Lithium-sulfur batteries at greater than 90% yield

Lyten recently announced it is consistently surpassing 90 percent yield from its automated battery production line, confirming the manufacturability of its lithium-sulfur battery utilizing a sulfur cathode and lithium metal anode.

The lithium-sulfur manufacturing performance has been achieved utilizing standard lithium-ion manufacturing equipment and processes. The conversion of lithium-ion equipment to produce lithium-sulfur batteries in Lyten’s pilot facility required 6 weeks and less than 2% of the total capital cost. This confirms Lyten’s ability to rapidly scale by converting existing Li-ion gigafactories to lithium-sulfur with minimal cost and time.

Graphene Manufacturing Group announces organizational restructuring to cut operating costs

Graphene Manufacturing Group (GMG) has announced it will be implementing a strategic organizational restructuring to reduce operating costs, while maintaining focus on key business objectives including graphene production, energy-saving product revenue, next-generation battery development, and supply chain enhancement.

The organizational overhaul is expected to cut operating costs by A$4.5 million (almost USD$3 million) per annum, according to a statement by the company.

Solidion Technology begins trading on NASDAQ, aims to advance eVTOL aircraft with graphene-enhanced batteries

Solidion Technology, an advanced battery technology solutions developer, began trading on NASDAQ (ticker symbol “STI”) on February 5, 2024. Solidion is the merged entity between Honeycomb Battery Company (HBC, Dayton, Ohio) and Nubia Brand International Co., a special purpose acquisition company (SPAC), based in Dallas, Texas.

Some see electric vertical takeoff and landing (eVTOL) aircraft as the next urban transportation technology breakthrough. At the heart of an eVTOL aircraft is a heavy battery pack. The amount of energy that can be stored in a battery pack with a reduced mass must be significantly increased before the eVTOL industry can literally take off. It is estimated that eVTOL aircraft needs a battery system with a gravimetric energy density > 400 Wh/kg. For an air taxi to carry more passengers, a battery cell energy density higher than 450 or even 500 Wh/kg will be required.

Lyten's graphene-enhanced lithium-sulfur batteries selected as the power source for Chrysler's new Halcyon Concept electric vehicle

Chrysler recently announced its Halcyon Concept electric vehicle, that plans to incorporate Lyten’s lithium-sulfur EV batteries as part of its goal to achieve a lighter weight and longer-range vehicle powered by batteries that utilize no nickel or cobalt.

Chrysler's Halcyon Concept EV. image credit: BusinessWire

Chrysler’s announcement states the Halcyon "envisions incorporating breakthrough Lyten 800V lithium-sulfur EV batteries that do not use nickel, cobalt or manganese, resulting in an estimated 60% lower carbon footprint than today's best-in-class batteries and a pathway to achieve the lowest emissions EV battery on the global market."

Log9 and Trinity Cleantech join forces to develop interoperable charging network

Log9 Materials, an innovator in EV charging technologies which has been working on graphene-based battery solutions, and Trinity Cleantech, a comprehensive provider of sustainable solutions, have reportedly announced a strategic partnership aimed at advancing India's electric vehicle (EV) industry. The companies will work to establish an interoperable charging network.

Trinity Cleantech plans to deploy 2,000 public charging stations under its brand “Thunder+” across India by the end of the next financial year. It plans to lead the market in Type 6 fast chargers, which represent the next-generation standard for charging speed and convenience. Trinity’s Thunder Platform is designed to seamlessly integrate with Log9’s “Instacharge” platform, streamlining operations and enhancing user experience. They have committed to adhering to the BCA LEV DC standard (IS 17017-25 & IS 17017-2-6), which provides users with the confidence to charge anywhere securely. As the EV landscape continues to evolve, Log9 and Trinity are dedicated to adapting to technological advancements in connectors, protocols, and payment gateways, ensuring continued compatibility for years to come.

Graphene-Info updates its Graphene Batteries Market Report

Today we published a new edition of our Graphene Batteries Market Report, with all the latest information. The batteries market is extremely active, as demand from EVs and mobile applications increases R&D efforts, and graphene is seen as a potential material to increase capacity, decrease charging times and improve other performance metrics. This is a major release that contains the latest company updates, projects, research publications and more.

Reading this report, you'll learn all about:

- The advantages of using graphene in batteries

- The different ways graphene can be used in batteries

- Various types of graphene materials

- What's on the market today

The report package also provides:

- A list of all graphene companies involved with batteries

- Detailed specifications of graphene-enhanced anode materials

- Personal contact details into most graphene developers

- Free updates for a year

This Graphene Batteries market report provides a great introduction to graphene materials used in the batteries market, and covers everything you need to know about graphene in this niche. This is a great guide for anyone involved with the battery market, nanomaterials, electric vehicles and mobile devices.

Pagination

- Page 1

- Next page