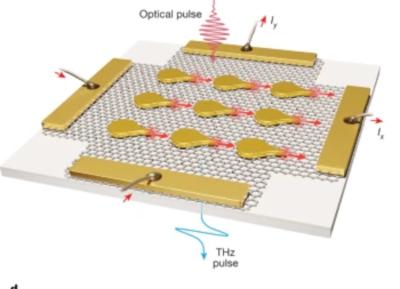

Researchers electrically manipulate a ‘chiral interface state’ in a 2D material

Researchers from Purdue University, University of California, Lawrence Berkeley National Laboratory and Japan's National Institute for Materials Science have managed to electrically manipulate a ‘chiral interface state’ in twisted monolayer-bilayer graphene, with potential for energy-efficient microelectronics and quantum computing.

The international research team, led by Lawrence Berkeley National Laboratory (Berkeley Lab), has taken the first atomic-resolution images and demonstrated electrical control of a chiral interface state – an exotic quantum phenomenon that could help researchers advance quantum computing and energy-efficient electronics.