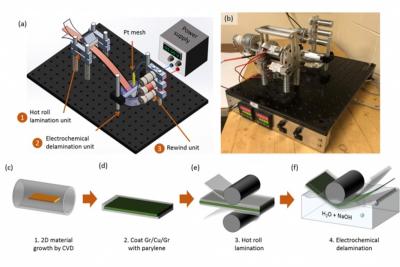

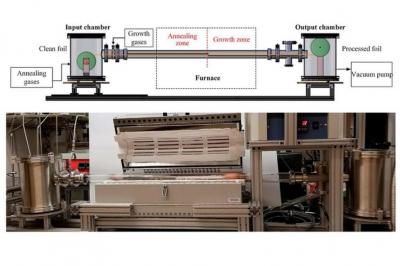

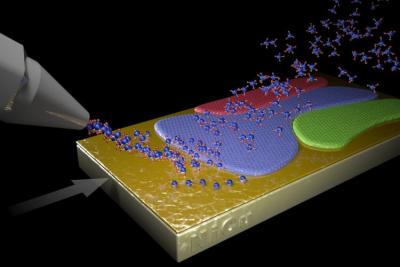

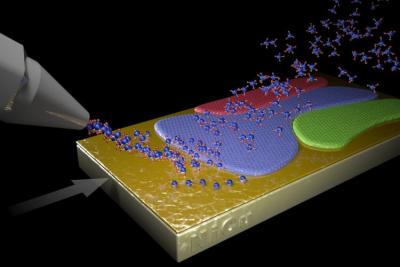

A team led by the Department of Energy’s Oak Ridge National Laboratory, that also included scientists from University of Tennessee, Rice University and New Mexico State University, has developed a new method to produce large, monolayer single-crystal-like graphene films more than a foot long. The novel technique may open new opportunities for producing high-quality graphene of unlimited size and in a way that is suitable for roll-to-roll production.

The ORNL team used a CVD method â but with a twist. They explained in this work how localized control of the CVD process allows evolutionary, or self-selecting, growth under optimal conditions, yielding a large, single-crystal-like sheet of graphene. Large single crystals are more mechanically robust and may have higher conductivity, ORNL lead coauthor Ivan Vlassiouk said. This is because weaknesses arising from interconnections between individual domains in polycrystalline graphene are eliminated. Our method could be the key not only to improving large-scale production of single-crystal graphene but to other 2D materials as well, which is necessary for their large-scale applications, he added.