New research by WMG at the University of Warwick has shown a novel approach to replacing graphite in the anodes of lithium-ion batteries using silicon, by reinforcing the anode’s structure with graphene girders. The team expects that this could more than double the life of rechargeable lithium-ion batteries by extending the operating lifetime of the electrode, and also increase the capacity delivered by such batteries.

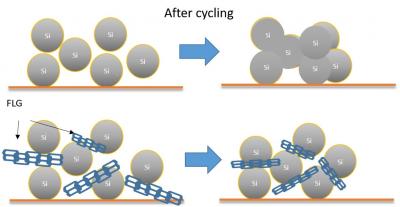

Researchers and manufacturers have been looking for a way to replace graphite in batteries with silicon for a long time, as it is an abundantly available element with ten times the gravimetric energy density of graphite. However, silicon has several performance issues that have so far limited such use. Due to its volume expansion upon lithiation silicon particles can electrochemically agglomerate in ways that impede further charge-discharge efficiency over time. Silicon is also not intrinsically elastic enough to cope with the strain of lithiation when it is repeatedly charged, leading to cracking and rapid degradation of the anode’s composite microstructure. This contributes significantly to capacity fade, along with degradation events that occur in the the cathode.

The researchers created anodes that were a mixture of 60% micro silicon particles, 16% FLG, 14% Sodium/Polyacrylic acid, and 10% carbon additives, and then examined the performance (and the changes in structure of the material) over a 100 charge-discharge cycles.

![]()

The team stated The flakes of FLG were mixed throughout the anode and acted like a set of strong, but relatively elastic, girders. These flakes of FLG increased the resilience and tensile properties of the material greatly reducing the damage caused by the physical expansion of the silicon during lithiation. The graphene enhances the long range electrical conductivity of the anode and maintains a low resistance in a structurally stable composite."

"More importantly, these FLG flakes can also prove very effective at preserving the degree of separation between the silicon particles. increases the chance that silicon particles become electrochemically welded to each other. This increased agglomeration increasingly reduces and restricts the electrolyte access to all the particles in the battery and impedes effective diffusion of lithium ions, which of course degrades the battery’s life and power output. The presence of FLG in the mixture tested by the WMG University of Warwick led researchers to hypothesize that this phenomenon is highly effective in mitigating electrochemical silicon fusion. This has been supported by systematic investigations

The research team has already begun further work on this technology, which will include further study and research as part of the graphene spearhead two year project led by Varta Micro-innovations, WMG at the University of Warwick is a partner along with Cambridge University, CIC, Lithops and IIT (Italian Institute of Technology). The main goal of that project is to advance in pre-industrial production of silicon/graphene composites and their subsequent processing into lithium-ion batteries for high-energy and high-power applications. As part of that project WMG at Warwick will be optimizing the electrode research, scale up and pouch cell manufacture of the optimized Li-ion batteries.