Graphenea increased their production capacity

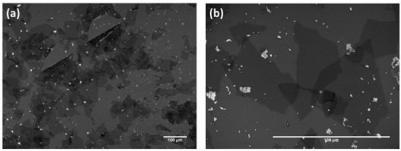

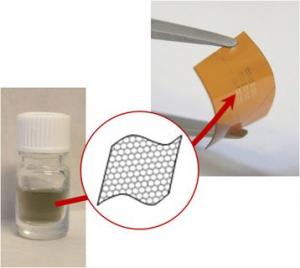

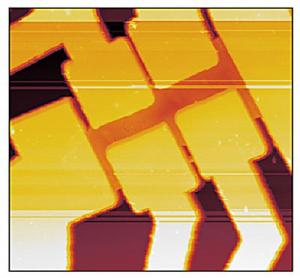

Graphenea says that they have finished the expansion works in their labs, and their production capacity has been increased X3 times. The company installed CVD growth and transfer equipment including an Aixtron BM Pro CVD system. The labs now have characterization facilities like Raman, SEM, FEI Titan TEM and AFM.

Graphenea says that they have finished the expansion works in their labs, and their production capacity has been increased X3 times. The company installed CVD growth and transfer equipment including an Aixtron BM Pro CVD system. The labs now have characterization facilities like Raman, SEM, FEI Titan TEM and AFM.

Graphenea's labs are based in the Nanotecnology Center CIC nanoGUNE in San Sebastian, Spain.