Durham Graphene Science qualified their bottom-up graphene production process, to seek further funds

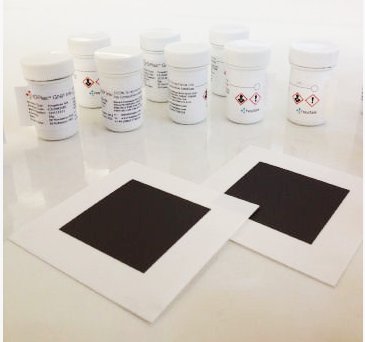

UK's Durham Graphene Science (DGS) has qualified their graphene production process, and the company is currently looking to raise further funds in the next 6-9 months so it can scale up its production capacity.

UK's Durham Graphene Science (DGS) has qualified their graphene production process, and the company is currently looking to raise further funds in the next 6-9 months so it can scale up its production capacity.

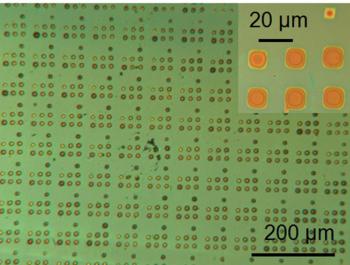

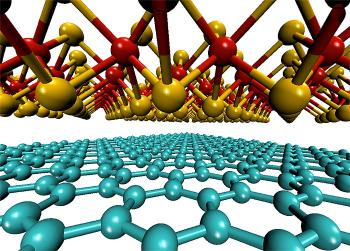

DGS (a spin-off from Durham University) developed a unique process for synthesizing graphene from carbon using sustainable and readily available cheap feed stocks in a bottom up chemical vapor deposition process. The company raised $1.8 million in its seed round of financing in February 2012 (valuation was about $3.5 million).