UK's Perpetuus enters the graphene market

UK-based Perpetuus Carbon Technologies announced that it entered the graphene supply market. The company will soon start production of customer-tailored surface modified graphene materials (excellent quality stacked graphene flakes) in its new 100 annual ton facility. The company can provide 50Kb batches within 48 hours and ton-sized orders within 28 days. The price of their graphene materials is £50 ($83) per kilogram.

UK-based Perpetuus Carbon Technologies announced that it entered the graphene supply market. The company will soon start production of customer-tailored surface modified graphene materials (excellent quality stacked graphene flakes) in its new 100 annual ton facility. The company can provide 50Kb batches within 48 hours and ton-sized orders within 28 days. The price of their graphene materials is £50 ($83) per kilogram.

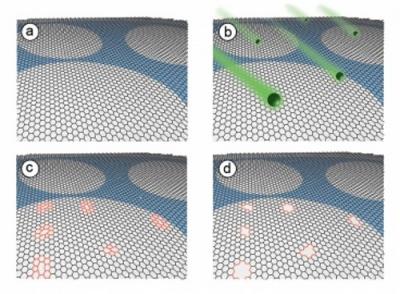

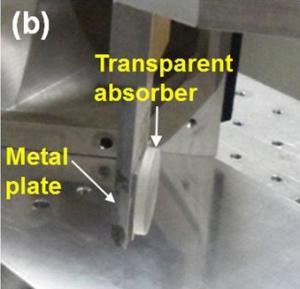

The company also holds an R&D arm (called Perpetuus Research and Development). The development activities focus on graphene based ink, and also include transparent condcutive films (for ITO replacement), stress strain actuators and printable coatable electrodes for use in lithium Ion batteries.