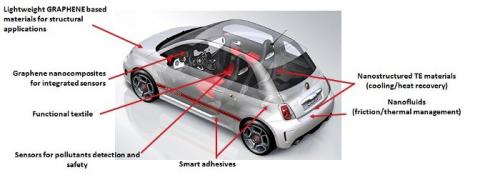

Fiat and other partners to investigate graphene-based materials for the automotive industry

One of the projects that was selected for the 2nd-stage of the EU's Graphene Flagship initiative is called iGCAuto, led by the University of Sunderland. This project partners will try and see how graphene and graphene-composite materials an be used in the automotive industry.

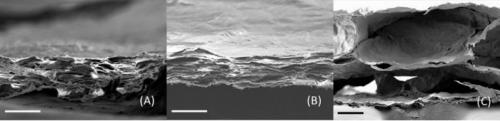

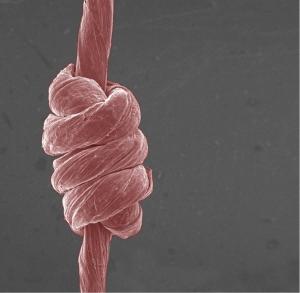

The focus of the project will be to find new materials that can make vehicles lighter and safer. The partners include Fiat, the Fraunhofer ICT, Interquimica, Nanesa and Delta-Tech. The partners will investigate different nanocomposites with different polymer matrices.