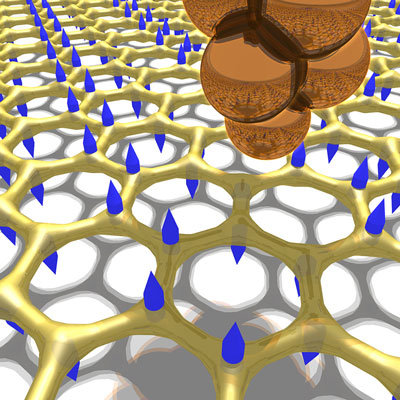

An international research team, led by scientists at the National Institute of Standards and Technology's (NIST) Center for Nanoscale Science and Technology, has developed a technique for measuring crystal vibrations in graphene.

Tunneling electrons from a scanning tunneling microscope tip excites phonons in graphene. The image shows the graphene lattice with blue arrows indicating the motion direction of that carbon atoms for one of the low energy phonon modes in graphene. (Image

Tunneling electrons from a scanning tunneling microscope tip excites phonons in graphene. The image shows the graphene lattice with blue arrows indicating the motion direction of that carbon atoms for one of the low energy phonon modes in graphene. (Image

In graphene, like in other crystals, when enough heat or other energy is applied, the forces that bond the atoms together cause the atoms to vibrate and spread the energy throughout the material. These vibrations, which have frequencies in the terahertz-range, are called phonons. Understanding phonon interactions can help gain knowledge on how to manipulate energy in a material, and can be crucial since learning effective ways to remove heat energy is vital to the continued miniaturization of electronics.

Group NanoXplore, a Montreal-based company specializing in the production and application of graphene and its derivative materials, announced the establishment of a European subsidiary. The new NanoXplore GmbH offices are located in Mainz, Germany in close proximity to the Frankfurt International Airport and in the German state of Rhineland-Palatinate (the center of the German chemical and plastics processing industry).

Group NanoXplore, a Montreal-based company specializing in the production and application of graphene and its derivative materials, announced the establishment of a European subsidiary. The new NanoXplore GmbH offices are located in Mainz, Germany in close proximity to the Frankfurt International Airport and in the German state of Rhineland-Palatinate (the center of the German chemical and plastics processing industry).