The best of 2015 - top graphene stories

2015 is pretty much over - and it was another interesting year for the graphene industry. Graphene-based products are slowly entering the market, but more importantly we see new projects, development and investments as people start to realize the amazing potential in this new material.

Here are the top 10 stories posted on Graphene-Info in 2015, ranked by popularity (i.e. how many people read the story):

- Sunvault Energy and Edison Power present a 10,000 Farad graphene supercapacitor (May 7)

- Sunvault's graphene-based supercapacitor declared to someday replace Lithium-ion batteries and compete with Tesla's battery aspirations (Apr 10)

- Stanford scientists make graphene-aluminum battery that charges quickly and lasts over 7,000 cycles (Apr 8)

- Graphene 3D Lab starts selling conductive graphene filament for 3D printing (Mar 16)

- Will Tesla's Roadster 3.0 use a graphene-enhanced battery? (Jan 5)

- Berkeley scientists design graphene-based loudspeakers and microphones (Jul 7)

- World's first commercial graphene-based supercapacitor chosen for use in spacecraft (May 5)

- IDTechEx's analyst explains his views on the graphene market (Sep 4)

- Scientists design a large-scale roll-to-roll graphene manufacturing process (May 21)

- Graphene-enhanced guitar shown at Graphene Live! (Jan 12)

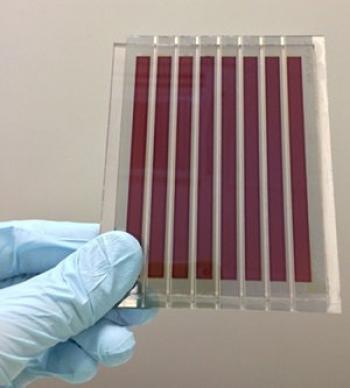

Graphene-enhanced perovskite PV

Graphene-enhanced perovskite PV