Grapeheneall starts selling low-cost GO and rGO

The Korean Grapheneall recently started to produce graphene oxide and reduced GO, in a low price that is enabled by the company's new oxidation and purification process that helps to decrease acidic waste. The company set up a factory and started production of GO and rGO in ton scale per month.

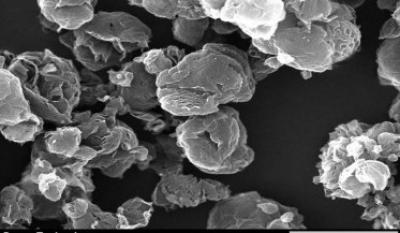

Grapheneall's SEM image of GO

Grapheneall's SEM image of GO

The unique purification process is said to be simple and take just one hour, as opposed to many other purification processes that are more time consuming. Grapheneall's production line is an automated system that is able to check and save real-time conditions, which assists the company in controlling the progress of production.