Graphene-based system may enable imaging of electrical activity in heart and nerve cells

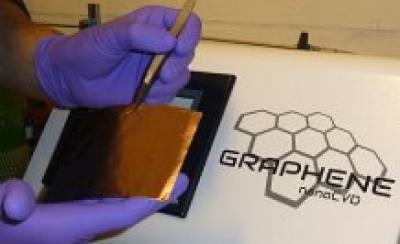

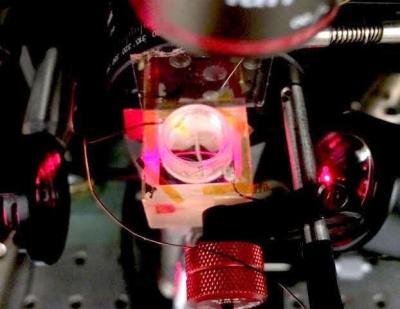

Researchers at the Berkeley Lab and Stanford University have used graphene as the film of an ultra-sensitive camera system designed for visually mapping tiny electric fields in a liquid. The new platform should permit single-cell measurements of electrical impulses traveling across networks containing 100 or more living cells. The researchers hope it will allow more extensive and precise imaging of the electrical signaling networks in our hearts and brains. Additional potential applications include the development of lab-on-a-chip devices, sensing devices and more.

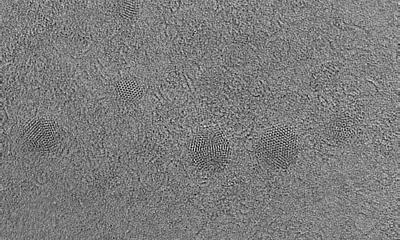

The team explains that the basic concept was examining how graphene could be used as a general and scalable method for resolving very small changes in the magnitude, position, and timing pattern of a local electric field, such as the electrical impulses produced by a single nerve cell. Other techniques have been developed to measure electrical signals from small arrays of cells, but these can be difficult to scale up to larger arrays and in some cases cannot trace individual electrical impulses to a specific cell. In addition, this new method does not perturb cells in any way, which is fundamentally different from existing methods that use either genetic or chemical modifications of the cell membrane.