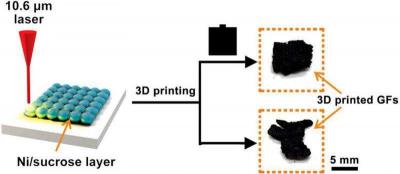

3D printed graphene aerogel awarded Guiness World Record

Guiness World Records has named a 3D printed graphene aerogel as "the least dense 3D printed structure". The 3D printed graphene aerogel, developed by a Kansas State University, University at Buffalo and Lanzhou University (China) team, weighs 0.5 milligrams per cubic centimeter. This achievement will be featured in the GUINNESS WORLD RECORDS 2018 Edition.

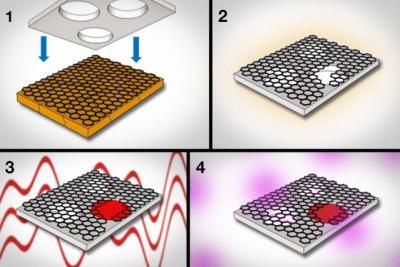

The way the researchers print the three-dimensional graphene is also regarded as revolutionary. The researchers use a modified inkjet printer that uses two nozzles. They 3D print droplets of a graphene oxide and water mixture in a freezer on a cold plate that is minus 20 degrees Celsius. This method creates a 3D ice structure of graphene and frozen water, which helps the graphene to maintain its shape.