Connecticut team designs a unique process for exfoliating graphene

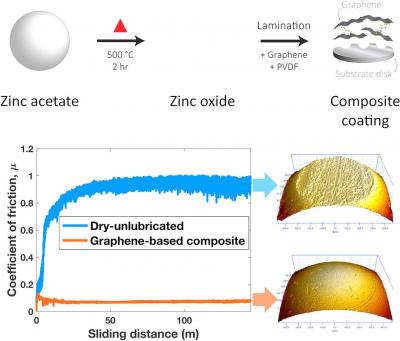

Researchers at the University of Connecticut, assisted by ones from the University of Akron, have patented a unique process for exfoliating graphene, as well as manufacturing innovative graphene nanocomposites that have potential uses in a variety of applications.

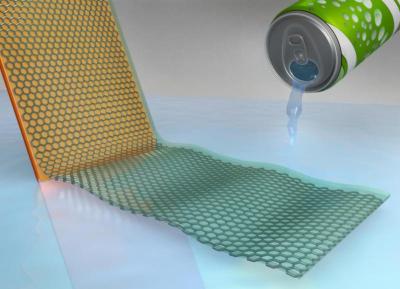

The new process doesn’t require any additional steps or chemicals to produce graphene in its pristine form. The innovation and technology behind our material is our ability to use a thermodynamically driven approach to un-stack graphite into its constituent graphene sheets, and then arrange those sheets into a continuous, electrically conductive, three-dimensional structure says the lead scientist in the study. The simplicity of our approach is in stark contrast to current techniques used to exfoliate graphite that rely on aggressive oxidation or high-energy mixing or sonication the application of sound energy to separate particles for extended periods of time. As straightforward as our process is, no one else had reported it. We proved it works.