MIT team demonstrates a novel method to mass-produce graphene in long rolls

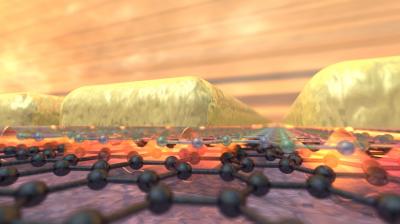

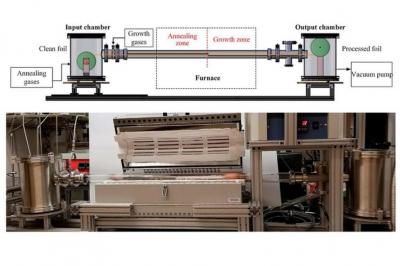

Researchers at MIT have developed a method that might enable the production of long rolls of high-quality graphene. The continuous manufacturing process can reportedly produce five centimeters of high-quality graphene per minute. The longest run was nearly four hours, and it generated around 10 meters of continuous graphene.

MIT is referring to the development as the first demonstration of an industrial, scalable method for manufacturing high-quality graphene that is tailored for use in membranes that filter a variety of molecules. These membranes could be used in biological separation or desalination, for example. The researchers drew from the common industrial roll-to-roll approach blended with chemical vapor deposition, a common graphene-fabrication technique.