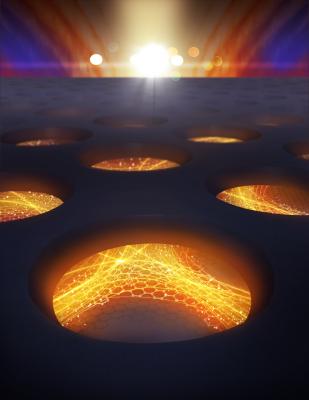

Perpetuus Advanced Materials announces long-term supply agreement with Vittoria Tires

A recent announcement was made by Perpetuus, stating that following 18 months of close collaboration between Perpetuus and Vittoria scientists, development work along with extensive laboratory to terrain testing has been completed on the first commercial elastomer to contain hybrid graphene fillers for the tire industry.

According to the statement, a new standard for nano surface engineered graphenes for cycle tires has now been established. This next generation graphene technology reportedly enables Vittoria to produce tires that are superior to all others within the cycle tire market.