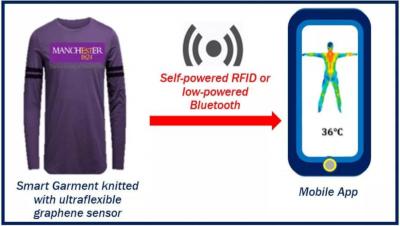

Graphene-based yarn to enable advanced wearable e-textiles

Researchers at the National Graphene Institute (NGI) have created a method to produce scalable graphene-based yarn. Such e-textiles may have great potential for sportswear, healthcare, aerospace, and fitness applications, and so are attracting research attention worldwide.

Integrating textile-based sensors into garments in the manufacturing process is still time-consuming and complex. It is also expensive non-biodegradable, unstable, metallic conductive materials are still being used. Now, the NGI researchers have developed a process that has the potential to produce tonnes of conductive graphene-based yarn. It is possible to do this using current textile machinery without any addition to production costs. The produces graphene-based yarn is also said to be flexible, cheap, biodegradable, and washable.