Researchers at the University of Göttingen have developed a new method that utilizes the unusual properties of graphene to electromagnetically interact with fluorescing (light-emitting) molecules. This method allows scientists to optically measure extremely small distances, in the order of 1 Angstron (one ten-billionth of a meter) with high accuracy and reproducibility for the first time. This enabled researchers to optically measure the thickness of lipid bilayers, the stuff that makes the membranes of all living cells.

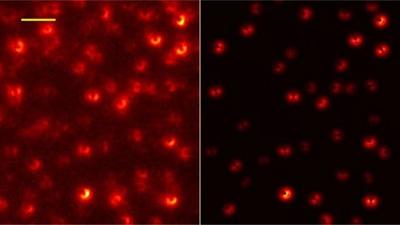

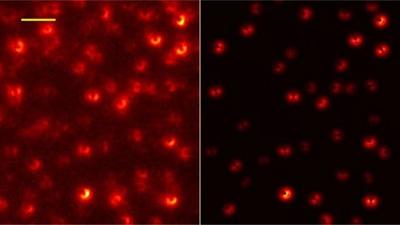

On the left: Image of single molecules on the graphene sheet. Such images allow scientists to determine the position and orientation for each molecule. Comparison with the expected image (right) shows excellent agreement. Credit: University of Göttingen

On the left: Image of single molecules on the graphene sheet. Such images allow scientists to determine the position and orientation for each molecule. Comparison with the expected image (right) shows excellent agreement. Credit: University of Göttingen

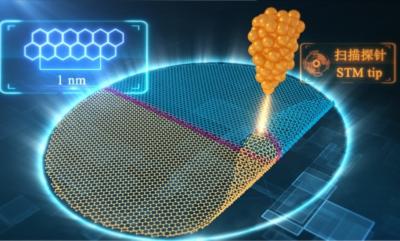

The University of Göttingen team, led by Professor Enderlein, used a single sheet of graphene, just one atom thick (0.34 nm), to modulate the emission of light-emitting (fluorescent) molecules when they came close to the graphene sheet. The excellent optical transparency of graphene and its capability to modulate through space the molecules' emission made it an extremely sensitive tool for measuring the distance of single molecules from the graphene sheet. The accuracy of this method is so good that even the slightest distance changes of around 1 Ã¥ngström (this is about the diameter of an atom or half a millionth of a human hair) can be resolved. The scientists were able to show this by depositing single molecules above a graphene layer. They could then determine their distance by monitoring and evaluating their light emission.