Skeleton Technologies to develop new production technology with €51 million support from German government

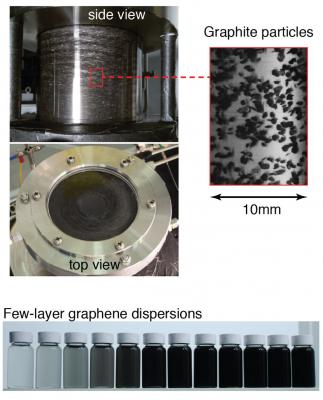

Skeleton Technologies recently announced plans to develop new production technology and fully automate manufacturing in its GroÃröhrsdorf factory. The manufacturer of graphene-enhanced supercapacitors has unveiled plans to develop a first-of-its-kind production technology for the manufacturing of its products, following the official support announced by German authorities. These plans include a fully-automated ultracapacitor production line in its GroÃröhrsdorf factory. The economies of scale provided by this new technology, combined with the use of Skeleton’s patented curved graphene material, is expected to dramatically drive the production costs down.

recently announced plans to develop new production technology and fully automate manufacturing in its GroÃröhrsdorf factory. The manufacturer of graphene-enhanced supercapacitors has unveiled plans to develop a first-of-its-kind production technology for the manufacturing of its products, following the official support announced by German authorities. These plans include a fully-automated ultracapacitor production line in its GroÃröhrsdorf factory. The economies of scale provided by this new technology, combined with the use of Skeleton’s patented curved graphene material, is expected to dramatically drive the production costs down.

We are continuously investing in R&D whether it is improving the performance of our products or the process in which we make those products. The next stage of our production will see an implementation of fully automated Industry 4.0 manufacturing techniques a first-of-its-kind in the ultracapacitor industry. Coupled with our curved graphene material, we are able to dramatically decrease the cost of ultracapacitors. The ultracapacitor industry is in the same situation as lithium-ion batteries were in 1999, but our advancements in core technology and production capabilities will be able to show a cost reduction faster than for any other energy storage technology. We have a clear road map to lower it by almost 90% after completion of our 5 years project, says Taavi Madiberk, CEO and co-founder of Skeleton Technologies, in a press release.