A way to cut CO2 levels, produced from burning fossil fuels and released into the atmosphere, is through carbon capture, a chemical technique that removes CO2 from emissions ("postcombustion"). The captured CO2 can then be recycled or stored in gas or liquid form, a process known as sequestration.

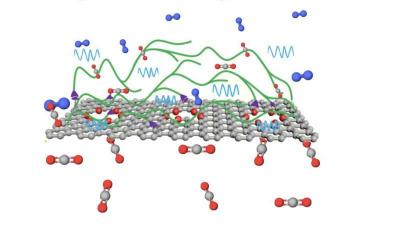

CO2-selective polymeric chains anchored on graphene effectively pull CO2 from a flue gas mixture. Credit: KV Agrawal (EPFL)

CO2-selective polymeric chains anchored on graphene effectively pull CO2 from a flue gas mixture. Credit: KV Agrawal (EPFL)

Carbon capture can be done using high-performance membranes, which are polymer filters that can specifically pick out CO2 from a mix of gases, such as those emitted from a factory's flue. These membranes are environmentally friendly, they don't generate waste, they can intensify chemical processes, and can be used in a decentralized fashion. They are now considered as one of the most energy-efficient routes for reducing CO2 emissions. Now, scientists (led by Kumar Varoon Agrawal) at Ecole Polytechnique Federale de Lausanne (EPFL) have developed a new class of high-performance membranes that exceed post-combustion capture targets by a significant margin. The membranes are based on single-layer graphene with a selective layer thinner than 20 nm, and have highly tunable chemistry, meaning that they can pave the way for next-generation high-performance membranes for several critical separations.

"Functionalizing CO2-selective polymeric chains on nanoporous graphene allows us to fabricate nanometer-thick yet CO2-selective membranes," says Agrawal. "This two-dimensional nature of the membrane drastically increases the CO2 permeance, making membranes even more attractive for carbon capture. The concept is highly generic, and a number of high-performance gas separations are possible in this way."

Sounds promising but how does it apply to any vehicle.

Yes It does sound promising ,but how does it apply to any vehicle United States has vehicles as small as motor cycles to as large as 50 ton vehicles.When can we actual applications?

T

Fouling

How does the membrane perform in terms of fouling and how is it regenerated once fouled?

New wave catalytic converters

New wave catalytic converters?