A team of researchers at the University of Minnesota and Northwestern University, USA, have developed a printing method to produce flexible graphene micro-supercapacitors with a planar architecture suitable for integration in portable electronic devices.

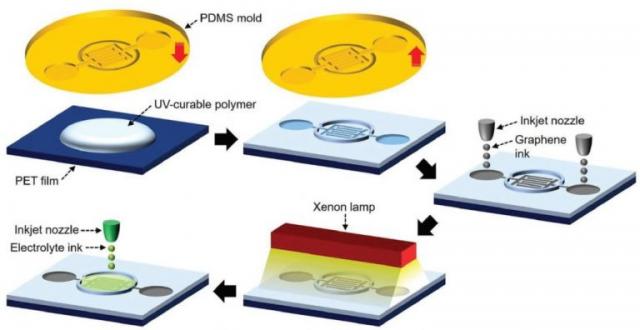

The new process, referred to as ‘self-aligned capillarity-assisted lithography for electronics’ (SCALE), begins with the creation of a polymer template, generated by stamping a UV-curable polymer with a PDMS mold. High-resolution inkjet printing is then used to deposit a graphene ink into the template, which is annealed using a xenon lamp to form the electrodes. In the final step, a polymer gel electrolyte is printed onto the template over the electrodes to complete the configuration.

Arrays of micro-supercapacitors were printed onto a flexible PET film and their electrochemical performance was tested. It was reported that all printed devices were found to be functional, and it was determined that fewer electrode fingers provided a higher specific capacitance value, with larger energy and power densities.