Korean researchers developed a new way to pattern graphene - using a motorized movable roller. The researchers made a transistor from a graphene that was patterned with a polymer solution in this method. This may lead to a low-cost graphene patterning technology on a large scale.

The researchers say that their self-assembly-mediated process can be used to fabricate graphene micro-patterns on flexible substrates. In their specific research, highly ordered patterns of PMMA polymer solution (also known as Plexiglas when in solid form) were produced onto a single-layer graphene film prepared on a flexible substrate. The PMMA is useful as a protector while etching the graphene by a plasma treatment, and was later washed off.

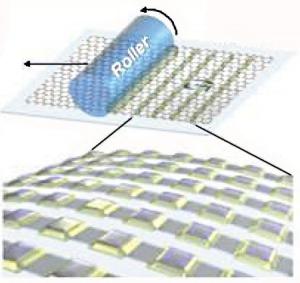

Patterning was done by positioned a roller on top of the graphene, and pushing it by an upper motorized plate at a defined speed. When the researchers loaded the PMMA solution in a confined space formed between the roller and graphene surface, the PMMA solution edge (i.e., contact line) undergoes continuous stick-slip motion due to the competition between the pinning and capillary forces. As a result, periodically striped PMMA patterns are formed on the graphene surface over large areas. This method produced PMMA stripes with nearly equivalent spacing and a width of about 18 micrometers. By rotating the graphene film 90°, the researchers could also fabricate cross-striped patterns.