Vanderbilt engineers recently designed a simple defect-sealing technique to correct variations in pore size in graphene membranes. The researchers reported a breakthrough in scalable fabrication of graphene membranes with a sealing technology that corrects variations in the pore size so they remain small enough to trap salt ions and small molecules but allow water to pass.

One of the most complex engineering challenges when making membranes so thin is to maintain integrity in the uniformity of the pores, which requires drilling atomically precise holes in a one-atom thick sheet of carbon atoms. A single large hole can cause high leakage and compromise membrane performance, said Piran Kidambi, assistant professor of chemical and biomolecular engineering.

Kidambi and the other team members designed a simple defect-sealing technique based on a gatekeeper analogy. While most prior studies formed holes in graphene membranes as a final step, this team turned the process around. They formed holes in the graphene first using a low-temperature chemical vapor deposition (CVD) process followed by ultra violet light in the presence of ozone gas and used the size of the holes as a gatekeeper.

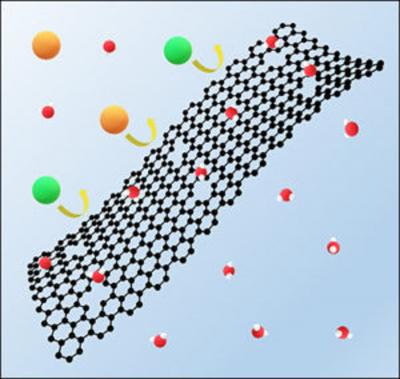

A sealant molecule on one side has to pass through the gate to meet another molecule on the other side and form a seal. If the size of the molecule is smaller than the gate, it will pass through, meet the other molecule and seal the gate. If the size of the molecule is larger than the gate, it will not pass and the gate will remain open.

Think of it like a fishing net that catches only large fish, said Peifu Cheng, postdoctoral scholar in chemical and biomolecular engineering and a member of Kidambi’s lab.

We show that a polymerization technique after nanopore formation in graphene not only seals larger defects (>0.5 nanometer) and macroscopic tears, but also successfully preserves the smaller sub-nanometer pores, Kidambi said.

The graphene membrane can separate 0.28 nanometer (water) from 0.66 nanometer (hydrated salt ions) via a simple size-selective defect sealing technique. For comparison, one inch is equal to 25,400,000 nanometers. The researchers used table salt (NaCl) and potassium chloride (KCl), a salt that occurs naturally seawater or underground brackish water, as well as the amino acid L-tryptophan and the water-soluble vitamin B-12 in their experiments.

To the best of our knowledge, this is the first demonstration of size-selective defect sealing for nanoporous atomically thin membranes, Kidambi said. In addition, we obtained water permeance 23 times higher than commercially available water treatment/desalination membranes, along with salt rejection greater than 97% and small molecule rejection of about 100%.

In terms of membrane upgrades and alleviating barriers to commercialization, the team’s graphene treatment is a novel advance. Flipping pore creation and creating a size-selective sealing technique is a significant contribution to membrane advancements, Kidambi said.

Their work has the potential for transformative advances in high-quality commercial graphene membranes that filter a variety of microscopic ions and molecules, including salts, proteins or nanoparticles, and relevant to industrial applications beyond water desalination, such as gas separations. Such membranes also should be useful for chemical, biological and medical research and the purification of substances used in pharmaceuticals.

Authors of the study include Vanderbilt graduate student Nicole Moehring and undergraduate Mattigan Kelly; Wonhee Ko, An-Ping Li and Juan Carlos Idrobo, Center for Nanophase Materials Science at Oak Ridge National Laboratory; and Michael Boutilier, Western University (Canada) chemical and biochemical engineering professor.