Graphene Flagship team creates photosensitive graphene-based "switches"

Partners of the European Project 'Graphene Flagship' at the University of Strasbourg and CNRS (France), along with an international team of collaborators, created new 'switches' that respond to light. The team combined light-sensitive molecules with layers of graphene and other 2D materials to create new devices that could be used in sensors, optoelectronics and flexible devices.

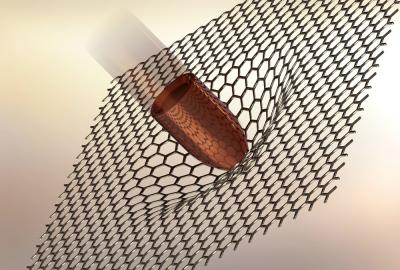

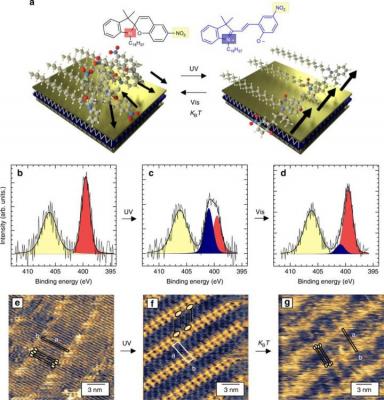

The researchers designed a molecule that can reversibly undergo chemical transformations when illuminated with ultraviolet and visible light. This molecule (a photoswitchable spiropyran) can be then attached to the surface of materials like graphene or molybdenum disulfide, thus generating an atomically precise hybrid macroscopic superlattice. When illuminated, the whole supramolecular structure experiences a collective structural rearrangement, which could be directly visualized with a sub-nanometer resolution by scanning tunneling microscopy.