Tackling graphene oxide's flammability issue may open the door to various applications

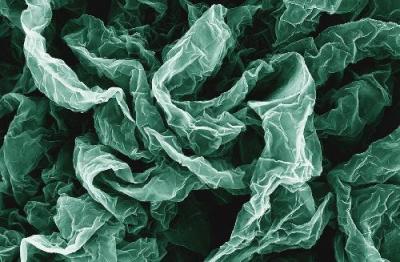

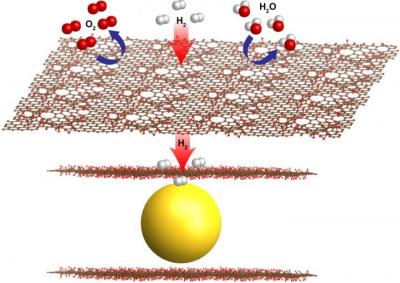

Researchers from the University of Arkansas have tackled the issue of graphene oxide's flammability; The team explains that scaling up the production of graphene-based materials is often problematic and dangerous due to GO's tendency to become explosive once airborne, so solving this problem may prove important.

In their work, the team established a relatively simple method to cross-link GO with Al3+ cations, in one step, into a freestanding flexible membrane. This membrane resists in-air burning on an open flame, at which non-cross-linked GO was burnt out within â¼5 s. With the improved thermal and water stabilities, the cross-linked GO film can help advance high-temperature fuel cells, electronic packaging, etc.