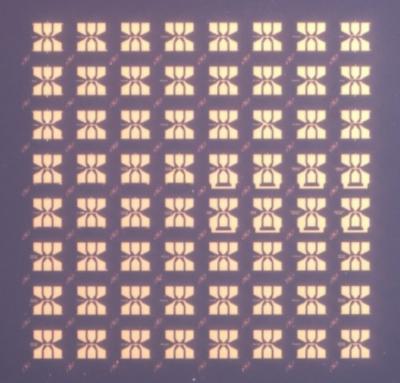

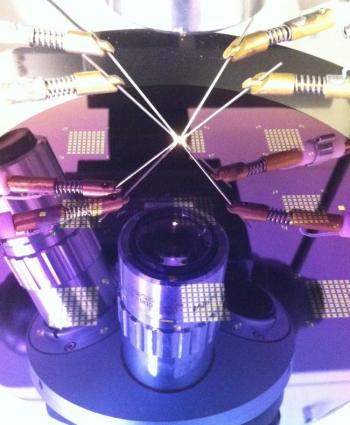

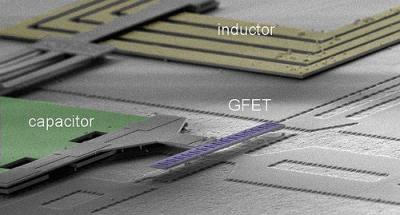

IBM researchers fabricated the world's most advanced G-FET based IC

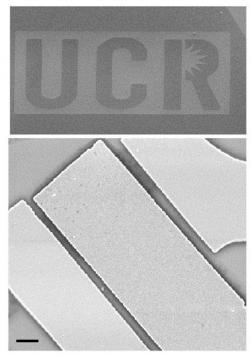

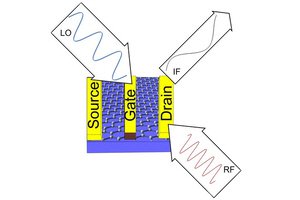

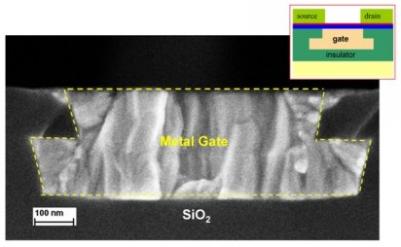

IBM researchers built a graphene (GFET) based radio frequency receiver IC which they say is the world's most advanced IC ever made of graphene - in fact it offers 10,000 times better performance and any previously reported effort.

IBM's circuit consists of three graphene transistors, four inductors, two capacitors, and two resistors. All circuit components are fully integrated into a 0.6 mm2 area and fabricated in a 200 mm silicon production line. The researchers say that those the circuits consume less than 20 mW power to operate, while also demonstrating the highest conversion gain of any graphene RF circuits at multiple GHz frequency.