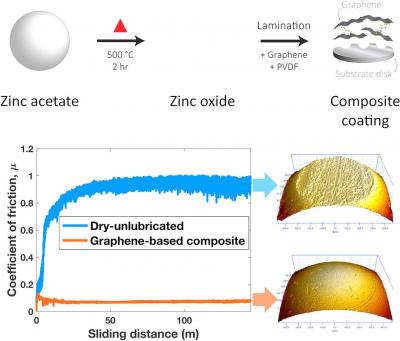

ANS launches a graphene-fortified polymer-bonded coating

Sweden-based Applied Nano Surfaces (ANS) launched a new product, Tricolit GO, one of the first graphene-enhanced low-friction coatings on the market today. Tricolit is available now from ANS, in easy-to-apply spray cans or in bulk. The product can be used to reduce friction and wear. ANS claims that the use of graphene allows a tenfold increase in the coating’s mechanical strength and abrasion-resistance.

We have talked to ANS CTO, Boris Zhmud, and he revealed that ANS uses graphene dispersions from UK-based Applied Graphene Materials. Tricolit GO is still considered an "experimental" product. The development was financed by Sweden's SIO-Grafen.