Stretchable and ultrasensitive NO2 sensors based on rGO and MOS2 nanocomposites

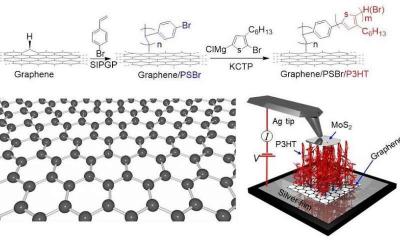

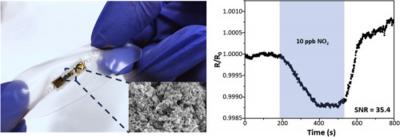

Researchers at Penn State, Northeastern University and five universities in China have developed and tested a stretchable, wearable gas sensor for environmental sensing.

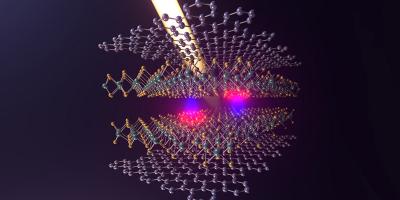

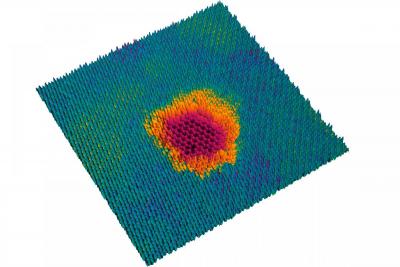

The sensor combines a newly developed laser-induced graphene foam material with a unique form of molybdenum disulfide and reduced-graphene oxide nanocomposites. The researchers were interested in seeing how different morphologies of the gas-sensitive nanocomposites affect the sensitivity of the material to detecting nitrogen dioxide molecules at very low concentration. To change the morphology, they packed a container with very finely ground salt crystals.