The U.S. Army funds expansion of "flash" process

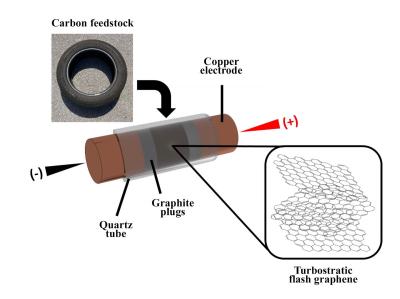

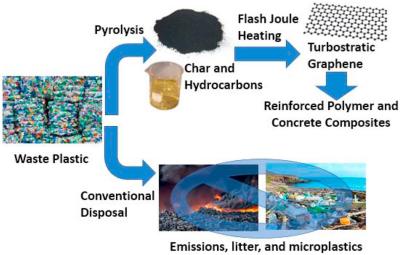

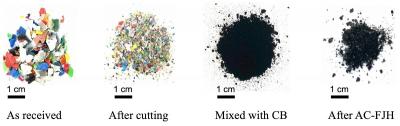

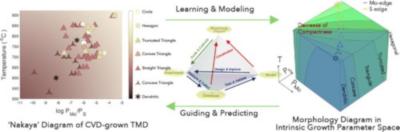

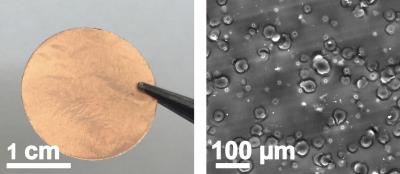

The Army Corps of Engineers will work with Prof. Tour and his collaborators at Rice University through a $5.2 million, four-year grant to expand the process that turns waste into graphene through flash Joule heating, to additional materials as well. Among the initiatives is a strategy to recover cobalt, lithium and other elements through the process developed by Tour’s group.

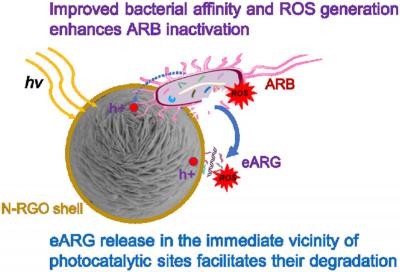

The grant through a Department of the Interior Cooperative Research and Development Agreement will allow the Rice-based team to extend the impact of its discovery that flashing food waste and other trash with a high-voltage jolt of electricity turns it into graphene. Through further experiments, the team realized the process could do much more. We’re pushing the idea that flash Joule heating can go way beyond just graphene, Tour said.