A research team, led by Soongeun Kwon from the Department of Nano Manufacturing Technology at the Korea Institute of Machinery and Materials (KIMM) and Professor Young-Jin Kim from the Department of Mechanical Engineering at the Korea Advanced Institute of Science and Engineering (KAIST), has reported the development of customized graphene-based e-textiles.

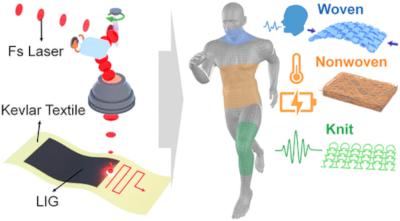

Unlike most conventional methods that rely on toxic chemicals or optical masks for patterning, the research team used laser-direct patterning technology to create laser-induced graphene (LIG) on e-textiles. This approach led to the production of graphene-based e-textiles. The team converted raw Kevlar textiles to electrically conductive laser-induced graphene (LIG) via femtosecond laser pulses in ambient air.

Traditional methods for manufacturing e-textiles have typically involved coating fabrics with conductive ink to render them electrically conductive and then weaving them with standard fabrics or incorporating a thin functional layer onto regular fabrics. These methods are associated with limited design flexibility and a complex manufacturing process. Additionally, there is a risk of harmful chemicals being released during production, which can hinder mass production.

The team reported that with its recently developed technology, the resulting LIG had high electrical conductivity and chemical reliability with a low sheet resistance of 2.86 Ω/□. Wearable multimodal e-textile sensors and supercapacitors were realized on different types of Kevlar textiles, including nonwoven, knit, and woven structures, by considering their structural textile characteristics. The nonwoven textile exhibited high mechanical stability, making it suitable for applications in temperature sensors and micro-supercapacitors. On the other hand, the knit textile possessed inherent spring-like stretchability, enabling its use in the fabrication of strain sensors for human motion detection.

Additionally, the woven textile offered special sensitive pressure-sensing networks between the warp and weft parts, making it suitable for the fabrication of bending sensors used in detecting human voices.

This direct laser synthesis of arbitrarily patterned LIGs from various textile structures could result in the facile realization of wearable electronic sensors and energy storage.