Graphene Oxide: Introduction and Market News

What is Graphene Oxide?

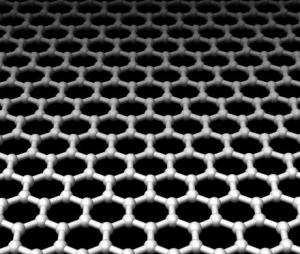

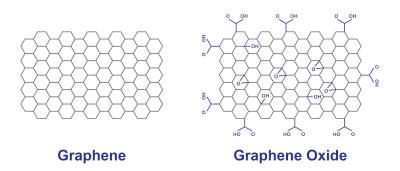

Graphene is a material made of carbon atoms that are bonded together in a repeating pattern of hexagons. Graphene is so thin that it is considered two dimensional. Graphene is considered to be the strongest material in the world, as well as one of the most conductive to electricity and heat. Graphene has endless potential applications, in almost every industry (like electronics, medicine, aviation and much more).

As graphene is expensive and relatively hard to produce, great efforts are made to find effective yet inexpensive ways to make and use graphene derivatives or related materials. Graphene oxide (GO) is one of those materials - it is a single-atomic layered material, made by the powerful oxidation of graphite, which is cheap and abundant. Graphene oxide is an oxidized form of graphene, laced with oxygen-containing groups. It is considered easy to process since it is dispersible in water (and other solvents), and it can even be used to make graphene. Graphene oxide is not a good conductor, but processes exist to augment its properties. It is commonly sold in powder form, dispersed, or as a coating on substrates.

Graphene oxide is synthesized using four basic methods: Staudenmaier, Hofmann, Brodie and Hummers. Many variations of these methods exist, with improvements constantly being explored to achieve better results and cheaper processes. The effectiveness of an oxidation process is often evaluated by the carbon/oxygen ratios of the graphene oxide.

Graphene oxide uses

Graphene Oxide films can be deposited on essentially any substrate, and later converted into a conductor. This is why GO is especially fit for use in the production of transparent conductive films, like the ones used for flexible electronics, solar cells, chemical sensors and more. GO is even studied as a tin-oxide (ITO) replacement in batteries and touch screens.

Graphene Oxide has a high surface area, and so it can be fit for use as electrode material for batteries, capacitors and solar cells. Graphene Oxide is cheaper and easier to manufacture than graphene, and so may enter mass production and use sooner.

GO can easily be mixed with different polymers and other materials, and enhance properties of composite materials like tensile strength, elasticity, conductivity and more. In solid form, Graphene Oxide flakes attach one to another to form thin and stable flat structures that can be folded, wrinkled, and stretched. Such Graphene Oxide structures can be used for applications like hydrogen storage, ion conductors and nanofiltration membranes.

Graphene oxide is fluorescent, which makes it especially appropriate for various medical applications. bio-sensing and disease detection, drug-carriers and antibacterial materials are just some of the possibilities GO holds for the biomedical field.

Buy Graphene Oxide

Graphene oxide is relatively affordable and easy to find, with many companies that sell it. It does, however, get confusing since different companies offer products that vary in quality, price, form and more - making the choice of a specific product challenging. If you are interested in buying GO, contact Graphene-Info for advisement on the right GO for your exact needs!

Further reading

- Introduction to graphene

- Graphene company database

- Graphene batteries

- Graphene supercapacitors

- The Graphene Handbook, our very own guide to the graphene market

- Graphene Oxide Market Report

Researchers develop fabrication strategy for improved graphene aerogels

While graphene aerogels have advantageous properties like extremely low weight, high porosity and good electrical conductivity, engineers who tried to use them to develop pressure sensors have encountered some difficulties.

Image credit: Nano Letters 2024

Specifically, many of these materials have an intrinsically stiff microstructure, which poses limits on their strain sensing capabilities. Researchers from Xi'an Jiaotong University, Northumbria University, UCLA, University of Alberta and other institutes recently introduced a new fabrication strategy for synthesizing aerogel metamaterials to overcome this limitation. This strategy fabricates a durable graphene oxide-based aerogel metamaterial that exhibits a remarkable sensitivity to human touch and motion.

Researchers track the quality of graphene oxide during long-term storage

A research team from Skoltech, MIPT, Emanuel Institute of Biochemical Physics of Russian Academy of

Sciences, and other scientific organizations recently conducted a study to determine which conditions are the most suitable for storing graphene oxide.

The results showed that the most optimal conditions for graphene oxide, when its properties will not change, are low temperatures and a lack of light.

Researchers develop improved hydrogen ion barrier films using pore-free graphene oxide membranes

Researchers from Kumamoto University and Hiroshima University have announced a significant development in hydrogen ion barrier films using graphene oxide (GO) without internal pores. This approach could be beneficial for protective coatings for various applications.

In their study, the research team successfully synthesized and developed a pore-free GO (Pf-GO) membrane with controlled oxygen functional groups. Traditionally, GO has been known for its high ionic conductivity, which made it challenging to use as an ion barrier. However, by eliminating the internal pores, the team created a material with dramatically improved hydrogen ion barrier properties.

New technique enables ultrafast 2D nanosheet assembly

Researchers from Nagoya University, Osaka University and National Taiwan University recently developed a method for the high-speed, large-area deposition of two-dimensional (2D) materials, including oxides, graphene oxide, and boron nitride. This innovative technique, known as the "spontaneous integrated transfer method," was discovered by chance; however, it could significantly improve the production of nanosheets.

Traditionally, methods like chemical vapor deposition (CVD) and the Langmuir-Blodgett (LB) technique have been employed for nanosheet fabrication. However, these methods have significant disadvantages, including difficulties in achieving uniform, large-area deposition and complications in the substrate transfer process. Aiming to develop a more effective deposition technology, the research team discovered a fascinating phenomenon completely by chance: when nanosheets get wet, they spontaneously align themselves on the surface of water, forming dense films within a mere 15 seconds. This process, termed the "spontaneous spreading phenomenon," suggested a more effective deposition technology.

Chang Robotics and Northwestern University’s INVO Lab introduce new graphene-enhanced packaging

Chang Robotics, an engineering company, and Northwestern University’s INVO Lab have announced a joint venture aimed at reducing contamination from microplastics and poly-fluoroalkyl substances (PFAS) in the US food supply.

This collaboration has led to the development of GOEco, an initiative that shows that very small amounts of graphene oxide can be infused into paper products or compostable packaging materials to replace plastic and PFAS. GOEco’s primary goal is to replace the widespread use of plastics in food packaging, such as paper plates and disposable utensils. The patent-pending technology helps enhance the environmental friendliness of disposable tableware without compromising functionality.

Researchers propose chromatography-like separation mechanism with UV-rGO membranes

Researchers from Pacific Northwest National Laboratory have found that reducing graphene oxide (GO) membranes with ultraviolet (UV) light alters the oxygen functional groups on the GO surface. This modification results in a different, chromatography-like separation mechanism that is selective for charge rather than size.

Image credit: Chemical Engineering Journal

Developing efficient, selective, and scalable separations for critical materials, including lithium and magnesium, is essential to meeting the increasing demands for clean energy technologies and alleviating challenges with domestic supply chains. GO membranes have shown promise for separating ions from mixed solutions based on size.

Graphene-Info releases a new edition of its Graphene Oxide Market Report

Today we published a new edition of our Graphene Oxide Market Report, with all the latest information, including new research activities related to GO. Our market report is a comprehensive guide to graphene oxide (and r-GO) materials and their promising applications in energy storage, composite materials, bio-medical, water treatment and more.

Reading this report, you'll learn all about:

- The difference between graphene oxide and graphene

- Graphene oxide properties

- Possible applications for graphene oxide

- Reduction of graphene oxide to r-GO

The report package also provides:

- A list of prominent GO research activities

- A list of all graphene oxide developers and their products

- Datasheets for over 20 different GO materials

- Free updates for a year

This Graphene Oxide market report provides a great introduction to graphene oxide materials and applications, and covers everything you need to know about GO materials on the market. This is a great guide for anyone interested in applying graphene oxide in their products.

NematiQ GO membrane receives WaterMark Certification

Australia-based NematiQ has announced that after more than a decade of work, the NematiQ Graphene Oxide membrane has obtained WaterMark certification, solidifying its status as a safe product for water filtration.

The Australian WaterMark Certification Scheme is a mandatory scheme for plumbing and drainage products of a certain type. Certification ensures products are fit for purpose and appropriately authorized for use in plumbing and drainage installations. The Australian Building Codes Board administers and manages the Scheme.

Researchers develop method to create stretchable and tough graphene films

Researchers have been working on creating elastic and tough graphene films, but it has proven quite challenging so far. Now, researchers at Shanghai Jiao Tong University have introduced a method to overcome this hurdle: they linked graphene nanolayers via "extendable" bridging structures.

Image credit: Angewandte Chemie

The special properties of graphene nanolayers often drop off when the layers are assembled into foils, because they are only held together by relatively weak interactions—primarily hydrogen bonds. Approaches that attempt to improve the mechanical properties of graphene foils by introducing stronger interactions have only been partially successful, leaving room for improvement in the stretchability and toughness of the materials. The research team, led by Xuzhou Yan at Shanghai Jiao Tong University in China, chose a new approach: they cross-linked graphene nanolayers with mechanically interlocked molecules whose building blocks are not chemically linked, but rather inseparably spatially entangled. The researchers used rotaxanes as their links.

Researchers develop graphene oxide spray coating for antiviral protection of face masks

Researchers at Spain's IMDEA Materials Institute, Rey Juan Carlos University and Valladolid University have developed a new spray coating to improve the antiviral efficacy of personal protective equipment, notably face masks.

The team's system is based on nanoplatelets of graphene oxide (GO) spray coated via a simple one-step procedure over a poly(lactic acid) textile fabric, allowing a homogeneous coating. The incorporation of GO does not affect the textile structure nor its air permeability, while it increases its water contact angle, potentially preventing droplet trespassing.

Pagination

- Page 1

- Next page