Graphene applications: what is graphene used for?

Graphene is a one-atom-thick sheet of carbon atoms arranged in a honeycomb-like pattern. Graphene is considered to be the world's thinnest, strongest and most conductive material - of both electricity and heat. All of these properties are exciting researchers and businesses around the world - as graphene has the potential to revolutionize entire industries - in the fields of electricity, conductivity, energy generation, batteries, sensors and more.

Mechanical strength

Graphene is the world's strongest material, and can be used to enhance the strength of other materials. Dozens of researchers have demonstrated that adding even a trace amount of graphene to plastics, metals or other materials can make these materials much stronger - or lighter (as you can use a smaller amount of material to achieve the same strength).

Such graphene-enhanced composite materials can find uses in aerospace, building materials, mobile devices, and many other applications.

Thermal applications

Graphene is the most heat conductive found to date. As graphene is also strong and light, it means that it is a great material for making heat-spreading solutions, such as heat sinks or heat dissipation films. This could be useful in both microelectronics (for example to make LED lighting more efficient and longer lasting) and also in larger applications - for example thermal foils for mobile devices. Huawei's latest smartphones, for example, have adopted graphene-based thermal films.

Energy storage

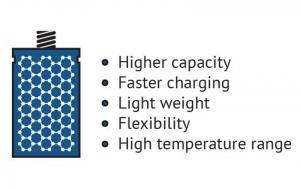

Since graphene is the world's thinnest material, it also extremely high surface-area to volume ratio. This makes graphene a very promising material for use in batteries and supercapacitors. Graphene may enable batteries and supercapacitors (and even fuel-cells) that can store more energy - and charge faster, too.

The advantages of graphene batteries

The advantages of graphene batteries

Coatings ,sensors, electronics and more

Graphene has a lot of promise for additional applications: anti-corrosion coatings and paints, efficient and precise sensors, faster and efficient electronics, flexible displays, efficient solar panels, faster DNA sequencing, drug delivery, and more.

Graphene is such a great and basic building block that it seems that any industry can benefit from this new material. Time will tell where graphene will indeed make an impact - or whether other new materials will be more suitable.

Lyten plans $1B Lithium-Sulfur battery Gigafactory in Nevada

U.S-based Lyten announced plans to invest more than $1 billion to build the world’s first Lithium-Sulfur battery gigafactory. The facility will be located near Reno, Nevada, and will have the capability to produce up to 10 GWh of batteries annually at full scale. Phase 1 of the facility is scheduled to come online in 2027.

Lyten’s proprietary processes permanently sequester carbon from methane in the form of 3D Graphene and utilize the supermaterial to develop decarbonizing applications. Lyten has received more than $425 million in investment from companies including Stellantis, FedEx, Honeywell, Walbridge, the European Investment Fund, and the Luxembourg Future Fund.

Researchers design a graphene-based 'electronic tongue' that detects liquid differences, spoilage, and food safety with AI accuracy

Researchers from Penn State University and NASA Goddard Space Flight Center recently developed an 'electronic tongue' based on a graphene-based ion-sensitive field-effect transistor, capable of identifying differences in similar liquids, such as milk with varying water content; diverse products, including soda types and coffee blends; signs of spoilage in fruit juices; and instances of food safety concerns. The team also found that results were even more accurate when artificial intelligence (AI) used its own assessment parameters to interpret the data generated by the electronic tongue.

Graphene ISFET chip mounted on a printed circuit board (PCB). Image from: Nature

The sensor and AI can broadly detect and classify various substances while collectively assessing their respective quality, authenticity and freshness. This assessment has also provided the researchers with a view into how AI makes decisions, which could lead to better AI development and applications, they said.

Researchers design graphene-based RF NEMS switches with excellent performance

Researchers from the Taiyuan Institute of Technology have introduced a novel graphene RF NEMS capacitive switch and conducted an extensive analysis of its RF performance within the UWB frequency range of DC ~ 140 GHz.

Schematic representation of the proposed graphene RF NEMS capacitive switch: (a) a 3D isometric view; (b) a top view. Image credit: Scientific Reports

The monolayer graphene RF NEMS switch is characterized by its low pull-in voltage, rapid switching time, and superior RF performance, contrasting with the comparatively inferior performance of multilayer graphene RF NEMS switches.

DUER launches graphene-enhanced jacket

DUER, an innovative denim company, has launched its new Performance Flannel that is enhanced with graphene. The fabric is said to regulate body temperature without feeling heavy, fight static and stay fresh longer.

“Graphene caught our attention as a Nobel prize-winning nano-fiber with exceptional performance properties that don’t impact a fabric’s weight, breathability, or soft feel,” said Gary Lennett, CEO of DUER. “We’ve integrated graphene into our Performance Flannel to provide enhanced thermal regulation— keeping you warm when it’s cold, and cool when it’s hot. Added to that, it fights static and keeps clothing fresh longer, marking a significant step in the future of textiles.”

The new Alienware Pro Headset will include graphene-coated drivers

Alienware debuted its Pro Mouse and Keyboard in January at CES 2024, and now the company is introducing the Pro Headset as part of the series.

The headphones incorporate various technologies, including 50mm drivers that are coated with graphene to reduce distortion commonly found at higher frequencies.

AMD announces collaboration with Xyntra Chemicals

Advanced Material Development (AMD) has entered into a commercial and technical collaboration with Xyntra Chemicals, a prominent player in the supply, manufacture, and development of polymers. The collaboration aims to develop a range of unique customized latex polymers to support AMD’s colorimetric smart sensing technologies. These polymers will be enhanced by graphene, along with additional nanomaterials.

The immediate priority of the new partnership is to optimize Xyntra’s polymer technology to support the early-stage production of AMD's innovative vaccine vial monitor technology and create the production-ready formula that will enable Xyntra to manufacture the solution at scale under license.

First Graphene and Halocell enter agreement to supply graphene for perovskite solar cells

First Graphene has secured an agreement with Halocell Energy to supply graphene for the manufacture of perovskite solar cells.

The initial two-year agreement will result in First Graphene providing its PureGRAPH material to Halocell for use as a high-performing coating for perovskite solar cells. By incorporating PureGRAPH into its products, Halocell Energy hopes to expedite its manufacturing process and enhance light absorbing performance, which will enable the company to scale up commercial production to meet demand.

New platform allows scientists to study materials at the level of individual molecules

University of Illinois Chicago scientists have created a new platform to study materials at the level of individual molecules. The approach is a significant breakthrough for creating nanotechnologies that could revolutionize computing, energy and other fields.

Two-dimensional materials, such as graphene, are made from a single layer of atoms. Studying and designing these ultrathin materials requires highly specialized methods. The laboratory of Nan Jiang, associate professor of chemistry and physics at UIC, pioneered a new method to simultaneously examine the structural, electronic and chemical properties of these nanomaterials. The platform combines two scientific approaches — scanning probe microscopy and optical spectroscopy — to view materials and assess how they interact with chemicals.

Researchers combine graphene and silk for advanced microelectronics, wearables and next-gen computing applications

While silk protein has been used in designer electronics, its use is currently limited in part because silk fibers are a messy tangle of spaghetti-like strands. To address this, researchers from Pacific Northwest National Laboratory, University of Washington, Lawrence Berkeley National Laboratory, North Carolina State University and Xiamen University have developed a uniform two-dimensional (2D) layer of silk protein fragments, or "fibroins," on graphene.

Scheme of silk fibroin assembly on highly oriented pyrolytic graphite (HOPG) characterized by in situ AFM. Image from Science Advances

The scientists explained that their work provides a reproducible method for silk protein self-assembly that is essential for designing and fabricating silk-based electronics. They said that the system is nontoxic and water-based, which is vital for biocompatibility.

Graphene sensor functionalized by NiO could improve ammonia detection

Researchers from Korea, including ones from Seoul National University and Korea Research Institute of Standards and Science, have developed a room-temperature self-activated graphene gas sensor functionalized by nickel oxide (NiO) nanoparticles and demonstrated its application to wearable devices monitoring ammonia gas.

The team introduced NiO nanoparticles onto graphene micropatterns to create a highly selective and sensitive ammonia sensor that can operate effectively even in the demanding conditions of wearable electronics. This advancement represents a potential step forward in sensor technology, particularly for applications such as food quality monitoring and wearable devices that track air quality.

Pagination

- Page 1

- Next page