Researchers at the Center for Multidimensional Carbon Materials (CMCM) within the Institute for Basic Science (IBS), have demonstrated a graphene coating that protects glass from corrosion. Their research has been said to hold potential for solving problems related to glass corrosion in several industries.

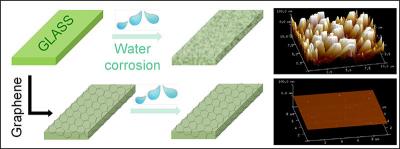

The IBS scientists grew graphene on copper and transferred either one or two atom-thick layers of graphene onto both sides of rectangular pieces of glass. The effectiveness of the graphene coating was evaluated by water immersion testing and observing the differences between uncoated and coated glass. After 120 days of immersion in water at 60 C, uncoated glass samples had significantly increased in surface roughness and defects, and reduced in fracture strength. In contrast, both the single and double layer graphene-coated glasses had essentially no change in both fracture strength and surface roughness.

Scientists have been looking at how to coat glass to protect it from damage - an ideal protective coating should be thin, transparent, and provide a good diffusion barrier to chemical attack. Graphene with its chemical inertness, thinness, and high transparency makes a very promising coating material. In addition, graphene's excellent chemical barrier properties block helium atoms from penetrating.

While different types of glass exist, ordinary glazing and containers are usually made of silicon dioxide (SiO2), sodium oxide (Na2O) along with minor additives. Glass corrosion begins with the adsorption of water on the glass surface. Hydrogen ions from water then diffuse into the glass and exchange with the sodium ions present on the glass surface. The pH of the water near the glass surface increases, allowing the silicate structure to dissolve. Corroded glass loses its transparency and its strength is reduced. Glass corrosion is a serious problem that plagues several industries, especially for the pharmaceutical, environmental and optical ones, and in particular in hot and humid climates.

The purpose of the study was to determine whether graphene grown by chemical vapor deposition on copper foils, a now established method, could be transferred onto glass, and protect the glass from corrosion. Our study shows that even one atom-thick layer of graphene does the trick, explains the team. In the future, when it is possible to produce larger and yet higher-quality graphene sheets and to optimize the transfer on glass, it seems reasonably likely that graphene coating on glass will be used on an industrial scale.

Impractical method

Growing graphene by CVD and transferring it to glass is a big expensive operation. Not something you would do for a dinner glass. There are other ways of coating glass with graphene that cost much less and that require much lower capital costs.