Graphene Coating: introduction and market status

What is a coating?

A coating is a covering that is applied to the surface of an object. The purpose of applying the coating may be decorative, functional, or both. Coatings are ubiquitous and can be found on walls, furniture, on all sorts of wires and printed circuits, the outside of houses and cars, and much more. In addition, the decorative duties of coatings span quite a broad spectrum.

Decorative coatings are mainly used for their color, texture or other visual property. Functional coatings are applied to change the surface properties of the substrate, such as adhesion, wettability, corrosion resistance, wear resistance and more. In some cases, the coating adds an entirely new property such as a magnetic response or electrical conductivity and forms an essential part of the finished product.

Coatings may be used in various processes, that are roughly divided into: vapor deposition, spraying, chemical and electrochemical techniques, roll-to-roll coating processes and other, less prominent techniques.

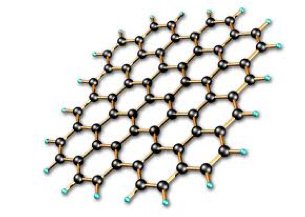

What is graphene?

Graphene is a two dimensional layer of carbon atoms, arranged in the form of a honeycomb lattice. It is touted as a “miracle material†because it is endowed with an abundance of astonishing traits - this thin, one atom thick substance is the lightest, strongest, thinnest material known to man, as well as the best heat and electricity conductor ever discovered - and the list does not end there. Graphene is the subject of relentless research and is thought to be able to revolutionize whole industries, as researchers work on many different kinds of graphene-based materials - each one with unique qualities and purpose.

Graphene for coatings

The vast selection of extraordinary properties that graphene possesses can open the door to many interesting types of coatings, paints, inks and more. Graphene's high resistivity can make for durable coatings that do not crack and are resistant to water and oil; its excellent electrical and thermal conductivity can be used to make various conductive paints, and a strong barrier effect can contribute to extraordinary anti-oxidant, scratch-resistant and anti-UVA coatings.

Graphene enables a wide array of functional coatings and paints, for many possible applications. Among these can be high performance adhesives enabled by graphene's high adhesion property, anti-bacterial coatings, solar paints (capable of absorbing solar energy and transmitting it), paints that provide isolation for houses, anti-rust coatings, anti-fog paints and UV ray blockers, non-stick coatings for various domestic applications (like frying pans and countertops) and even a much-hyped possibility (currently under scientific examination) of a coating that turns a regular wall into a screen.

Commercial activity

Graphene-enhanced products are yet to reach widespread commercialization. Nonetheless, given graphene’s impressive array of properties and the vigorous R&D that is taking place, graphene-enhanced coatings should not be too far away.

The Sixth Element Materials, a Chinese company that focuses on R&D, mass production and sales of graphene and related materials, showcased its graphene-zinc anti-corrosion primer used for offshore wind power tower, that can come at a competitive price compared with zinc rich epoxy primer.

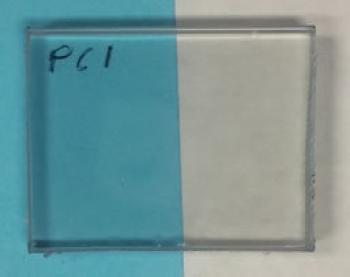

Garmor, the University of Central Florida spin-off formed to develop a new graphene oxide flakes production process, has developed graphene oxide-based coatings useful for limiting UV radiation damage to sensors and polymers. Garmor's transparent GO-films are reportedly derived from a commercially-viable and scalable process that can be readily implemented with minimal constraints.

Four layers of GO coating on polycarbonate

Four layers of GO coating on polycarbonate

The Spain-based Graphenano announced the launch of a graphene-based series of paints and coatings called Graphenstone in 2014. These are said to be very strong and also acts as a protective layer against environmental damage. Graphenstone is made from a graphene powder and limestone powder.

The British Electro Conductive Products released a sprayable transparent conductive coating based on a CNT and graphene platelets (GNP) hybrid material. TBA are targeting the food, electronics, pharmaceuticals and petrochemicals markets.The new ATEX-compliant product is available as a clear, anti-static aerosol, and it should also be available as bulk paint. Its application will safeguard electronic equipment used in explosive environments and bring it up to European standards.

Further reading

- Introduction to graphene

- Graphene Composites

- Graphene company database

- How to invest in the graphene revolution

- The Graphene Handbook, our very own guide to the graphene market

Graphene Manufacturing Group demonstrates improved heat sink performance with THERMAL-XR

In a recent PR, Graphene Manufacturing Group (GMG) shared that it continues to advance the commercialization of its THERMAL-XR coating system with the product being tested with companies in multiple industries, including on heat sinks for electronics.

Third-party modelling indicates that applying THERMAL-XR to heat sinks can reduce their size by up to 39% while maintaining the same thermal performance, the company highlighted. This reduction could lead to savings in weight and material costs. The technology also lowers the maximum temperature of heat sinks by 23%, improving their efficiency.

Sparc Technologies reports significant performance improvements achieved in graphene hnhanced water-based coatings

Sparc Technologies has announced the results of initial test work in water-based acrylic epoxy coatings. The testing has reportedly demonstrated significant corrosion performance improvements through the incorporation of low dosages of carefully selected grades of graphene compared to an unmodified control. Testing has been performed using two industry-recognized electrochemical measurement techniques.

Water-based coatings are gaining prominence due to better environmental credentials compared to more widely used solvent-based coatings which contain fossil fuel derived organic solvents. These results are the first evidence that Sparc has seen whereby graphene significantly improves the corrosion performance of water-based coatings. This extends Sparc’s reach into a new and rapidly growing area of the coatings market where there are clear performance challenges to address. It also complements Sparc’s flagship ecosparc® product range.

Graphene coating helps improve lithium-ion battery cathodes

Researchers at the California Institute of Technology (Caltech) have developed a method for coating lithium-ion battery cathodes with graphene, extending their life and performance. This recent effort may improve lithium-ion battery performance and reduce reliance on cobalt, an element frequently used in lithium-ion batteries that is difficult to source sustainably.

Image credit: Caltech

Caltech senior research scientist, David Boyd, has worked over the past decade to develop techniques for manufacturing graphene. In 2015, Boyd and colleagues discovered that high-quality graphene could be produced at room temperature. Prior to this, the production of graphene required extremely high temperatures, up to 1,000 degrees Celsius. After this breakthrough, they searched for new applications for graphene. Recently, Boyd teamed up with Will West, a technologist at Caltech's Jet Propulsion Laboratory (JPL), which Caltech manages for NASA. West specializes in electrochemistry and, in particular, in the development of improved battery technologies. Boyd and West set out to see if graphene could create an improved lithium-ion battery, which they have shown to be possible.

Sparc Technologies receives USD$730,000 R&D tax refund

Sparc Technologies has secured AUD$1.12 million (around USD$730,000) in an R&D tax refund, under the Australian Government's R&D Tax Incentive, relating to the 2024 financial year.

It was stated that this financial boost comes as a recognition of Sparc’s commitment to advancing sustainable technologies in high-performance coatings and polymers. This refund will strengthen the company’s cash position thereby providing continued support for Sparc's investment in Sparc Hydrogen, ecosparc® field trials and its work developing graphene based additives for high performance coatings and polymers

Graphene-based surface offers long-term scalable frost prevention

Researchers from Northwestern University and University of California have developed a strategy that prevents frost formation - the team reported a hybrid surface design that passively controls the diffusion of water vapor over a surface to sustain flat frost-free regions for long periods of time. The hybrid anti-frosting technique can prevent frosting for potentially weeks at a time and is scalable, durable and fabricated through 3D printing.

The team found that tweaking the texture of any surface and adding a thin layer of graphene oxide prevents 100% of frost from forming on surfaces for one week or potentially even longer. This is 1,000 times longer than current, state-of-the-art anti-frosting surfaces. As a bonus, the new scalable surface design is also resistant to cracks, scratches and contamination.

CRX Coatings launches new graphene-enhanced coating for marine applications

CRX Coatings, a Tennessee-based company specializing in graphene-formulated coatings, has entered into the boating industry by launching its new X21 Foul Release Bottom Paint.

CRX Coatings has developed a non-ablative, copper free, biocide-free graphene formula specifically for marine applications. Their innovative approach reportedly ensures maximum performance and durability for boat owners.

Carbon Waters opens its first production unit

Carbon Waters has announced a major milestone with the installation of its first production unit at its facility in Pessac.

Since its inception, Carbon Waters been active in the field of graphene-based performance additives. In 2022, it launched the recurring production of high-performance and ready-to-use additive range, Graph‘Up. These additives are dedicated to anticorrosion paints, mechanical reinforcement, and thermal property optimization of polymers and composites. Summer 2024 marked the arrival of Carbon Waters' first production unit. This investment helps Carbon Waters to multiply its production capacity by fifteen, a major step forward in meeting growing industrial demand.

GMG provides commercialization update on its THERMAL-XR coating

Graphene Manufacturing Group (GMG) has provided a business update on the commercialization progress of THERMAL-XR® Powered by GMG Graphene.

GMG and Nu Calgon have signed an agreement with a consultant to prepare and submit a Pre-Manufacture Notice (PMN) for its USA Environmental Protection Agency's (EPA) approval to import and sell in the USA, as previously announced in its THERMAL-XR® re-submission. The PMN application is expected to be submitted before the end of October and the potential approval is expected to take less than 12 months. The PMN will be substantially different from the Low Volume Exemption (LVE) PMN GMG previously submitted. The potential PMN EPA approval that GMG will be seeking is expected to be not limited by volume, application and any one particular sector, while the LVE PMN application was limited to 10 tonnes per annum, one application technique and the HVAC sector.

PETRONAS launches ProTough+ to enhance composite material strength

Malaysian energy company PETRONAS has launched its third graphene-based solution, ProTough+, under its Advanced Materials portfolio to capture new growth opportunities in line with its Energy Transition Strategy.

ProTough+ is an additive that enhances the strength of composite materials by improving their mechanical properties to achieve component light weighting, which is key in manufacturing and delivery of lower carbon solutions such as hydrogen mobility. Tests conducted on carbon fiber reinforced polymers enhanced with ProTough+ reportedly demonstrated an increase of more than 35% in tensile strength. This allows stronger composite parts to be manufactured with less materials, thus supporting fabrication of products that are lighter and more economical.

Sparc Technologies and 29Metals to test Sparc's Ecosparc graphene coatings

Sparc Technologies has announced the execution of a binding agreement (Trial Agreement) with Golden Grove Operations, a wholly owned subsidiary of 29Metals, an Australian miner of base and precious metals.

The Trial Agreement details the terms and conditions under which Sparc and 29Metals will conduct a collaborative field trial involving the application of an ecosparc-enhanced coating on steel processing plant infrastructure at the Golden Grove mine site in Western Australia. Ecosparc is the Company's flagship graphene based additive product.

Pagination

- Page 1

- Next page