Graphene CVD sheets - updates and market status

There are various methods to produce graphene materials, such as mechanical exfoliation of graphite, liquid-phase exfoliation and reduction of graphene oxide (GO), each with its own set of advantages and disadvantages. Chemical vapor deposition (CVD) is a method of producing graphene that has attracted much attention in the last decade and despite several shortcomings, is considered a leading approach to manufacture graphene, especially for applications like high-performance electronics and sensors, as it can yield high quality graphene sheets with a low defect count and good uniformity.

The CVD process

Generally speaking, the CVD method is based on gaseous reactants that are deposited on a substrate. The graphene is grown on a metallic surface like Cu, Pt or Ir, after which it can be separated from the metal and transferred to specifically-required substrates. When the gases contact the substrate inside the heated reaction chamber, a reaction occurs that creates a film of material on the substrate. The process can be simply explained as carbon-bearing gases that react at high temperatures (900-1100 °C) in the presence of a metal catalyst, which serves both as a catalyst for the decomposition of the carbon species and as a surface for the nucleation of the graphene lattice.

As was mentioned before, conditions like temperature, pressure, duration of time and many more can have a significant influence on the process and so must be carefully monitored.

Advantages and disadvantages

CVD can yield high quality graphene, with common characteristics that may include high homogeneity, imperviousness, high purity, fine grains, good control over layer number and more. However, CVD also comes with several disadvantages - namely a relatively high price of the equipment, toxic gaseous by-products and, as stated before, it is a rather sensitive process that is easily influenced by parameter changes. It is important to note that while CVD is a rather expensive method compared to other methods to produce lower-quality graphene, it is still probably the best way (to date) to acquire high quality graphene, since other ways to do that are even more expensive or complicated.

In addition, the separation (or exfoliation) of graphene from the substrate is known as challenging and it is tricky to accomplish without damaging the structure of the graphene or affecting the properties of the material. Another harrowing task is the creation of a uniform layer of graphene on a substrate, something that is continuously proving to not be easy at all.

Some approaches were and are still being developed to overcome this issue, like modifying the concentration of gases and incorporating spin coating methods, but this remains a challenge. However, despite these challenges, it is important to note that CVD is widely considered as an important and promising method to produce graphene, which is already in use, and will probably be even more so in the future, once further advancements are made. It is noteworthy that CVD is already a dominant manufacturing route for many other nanomaterials, and will assumably be in extremely common use once progress is made to resolve the issues that are currently hindering its acceptance.

Market status

While using the CVD method to produce graphene is definitely one the leading approaches in the world, it is still hindered by the challenges mentioned above. Thus, it is currently mostly limited to relatively small volumes and mainly restricted to R&D and academic uses.

However, graphene sheets produced via CVD methods are used in several applications like sensors, touch screens and heating elements. It is believed that once better answers are found to the questions of price and handling of CVD graphene, many more applications will start to appear.

Looking to buy CVD graphene sheets?

If you are interested in buying CVD graphene sheets, check out the Graphene Catalog that lists various CVD produced graphene sheets from several producers.

Versarien launches new graphene biosensor chip technology

Versarien has launched a new biosensor chip utilizing novel graphene barristor sensor platform technology. These graphene barristor devices, developed in South Korea by A Barristor Company (ABC), will utilize chemical vapor deposition (CVD) grown graphene, that is produced under a Versarien license. Versarien has signed a distribution agreement with ABC to distribute the products in the UK and Europe.

A barristor (triode device) is a new type of graphene‐based transistor with a Schottky barrier between graphene and silicon. The current modulation is amplified more than 10,000 times compared to graphene field‐effect transistors (GFET), enabling the barristor transistors to overcome many GFET limitations.

Graphene sensor functionalized by NiO could improve ammonia detection

Researchers from Korea, including ones from Seoul National University and Korea Research Institute of Standards and Science, have developed a room-temperature self-activated graphene gas sensor functionalized by nickel oxide (NiO) nanoparticles and demonstrated its application to wearable devices monitoring ammonia gas.

The team introduced NiO nanoparticles onto graphene micropatterns to create a highly selective and sensitive ammonia sensor that can operate effectively even in the demanding conditions of wearable electronics. This advancement represents a potential step forward in sensor technology, particularly for applications such as food quality monitoring and wearable devices that track air quality.

Graphene-Info launches a new version of its CVD Graphene Market Report

Today we published a new edition of our CVD Graphene Market Report, with all the latest information on this exciting material and market. The CVD graphene market is slowly emerging as applications and projects are increasing and the future looks bright for high-end graphene nanomaterials. This report adds the latest research updates, and a couple of new companies (a CVD graphene producer, and an application developer).

Reading this report, you'll learn all about:

- How does CVD graphene differ from other graphene types

- CVD graphene properties

- Possible applications for CVD graphene

- Available materials on the market

The report package also provides:

- A list of prominent CVD graphene research activities

- A list of all CVD graphene developers and their products

- Datasheets and brochures from over 10 different CVD graphene makers

- Free updates for a year

This CVD Graphene market report provides a great introduction to CVD graphene materials and applications, and covers everything you need to know about graphene produced by CVD. This is a great guide for anyone interested in applying CVD graphene in their products, or learning more about this promising new technology.

Researchers develop graphene membranes with pyridinic-nitrogen at pore edges for high-performance CO2 capture

Researchers at École Polytechnique Fédérale de Lausanne (EPFL) have developed advanced graphene membranes with pyridinic-nitrogen at pore edges, reportedly showing unprecedented performance in CO2 capture. This could mark a step towards more efficient carbon capture technologies.

Carbon capture, utilization, and storage (CCUS) is a technology that reduces carbon dioxide (CO2) emissions from hard-to-abate industrial sources such as power plants, cement factories, steel mills, and waste incinerators. But current capture methods rely on energy-intensive processes, which makes them costly and unsustainable. Researchers are working to develop membranes that can selectively capture CO2 with high efficiency, thereby reducing the energy and financial costs associated with CCUS. But even state-of-the-art membranes, such as polymer thin films, are limited in terms of CO2 permeance and selectivity, which limits their scalability. So, the challenge is to create membranes that can simultaneously offer high CO2 permeance and selectivity, crucial for effective carbon capture.

MEGAMORPH demonstrates its graphene-based display technology at Displayweek 2024

The EU-funded MEGAMORPH project, which started in 2022, demonstrated its graphene-based display technology at Displayweek 2024.

The idea behind the project is to use CVD graphene sheets (produced by Graphenea, a partner in the project) as the semi-transparent membranes in a Interferometric Modulator Display. These kinds of displays use mechanical micro-mirrors as pixels that modulate the ambient light without using power to generate light. IMOD displays are promising as they can offer very low power operation and high density displays.

Graphene-Info launches a new version of its CVD Graphene Market Report

Today we published a new edition of our CVD Graphene Market Report, with all the latest information on this exciting material and market. The CVD graphene market is slowly emerging as applications and projects are increasing and the future looks bright for high-end graphene nanomaterials.

Reading this report, you'll learn all about:

- How does CVD graphene differ from other graphene types

- CVD graphene properties

- Possible applications for CVD graphene

- Available materials on the market

The report package also provides:

- A list of prominent CVD graphene research activities

- A list of all CVD graphene developers and their products

- Datasheets and brochures from over 10 different CVD graphene makers

- Free updates for a year

This CVD Graphene market report provides a great introduction to CVD graphene materials and applications, and covers everything you need to know about graphene produced by CVD. This is a great guide for anyone interested in applying CVD graphene in their products, or learning more about this promising new technology.

GrapheneDx, General Graphene Corp and Sapphiros announce strategic partnership to industrialize graphene-based biosensors

GrapheneDX, General Graphene Corporation and Sapphiros have announce a strategic partnership to industrialize graphene-based biosensors for medical devices used to diagnose a variety of diseases at the point-of-care and in consumer settings.

GrapheneDx is an in vitro diagnostics company focused on improving diagnostic capability at the point-of-care and in consumer settings. The company is an expert in functionalizing graphene to create graphene field effect transistors (GFETs), which are biosensors that can be used to detect disease in biological samples. GrapheneDx's medical devices are designed to provide lab-quality accuracy, deliver results in less than 5 minutes and be simple enough to be performed both at the point of care and by patients without the supervision of a medical professional. The company's GFET platform is versatile, demonstrating performance across a variety of disease states (sexually transmitted infections, respiratory disease, cardiac disease, concussion and others) and sample types (stool, urine, swabs, blood, etc.), with little or no sample preparation. Additionally, the platform is capable of multiplexing numerous analytes concurrently with a single patient sample. GrapheneDx's first tests will be for the diagnosis of sexually transmitted infections, including Chlamydia and Gonorrhea, using a noninvasive, easy to collect urine sample.

Graphene Square Electronics launches crowdfunding campaign for its Kitchen Styler

Graphene Square Electronics has launched a crowdfunding campaign on Kickstarter to raise funds for what the Company calls "the first graphene powered appliance - Kitchen Styler".

According to Graphene Square Electronics, it is the "first and only appliance to use graphene as its sole source of heat". It is said to use CVD graphene in its design.

Graphene-Info launches a new version of its CVD Graphene Market Report

Today we published a new edition of our CVD Graphene Market Report, with all the latest information on this exciting material and market. The CVD graphene market is slowly emerging as applications and projects are growing fast, giving high hopes for the future market of high-end graphene nanomaterials.

Reading this report, you'll learn all about:

- How does CVD graphene differ from other graphene types

- CVD graphene properties

- Possible applications for CVD graphene

- Available materials on the market

The report package also provides:

- A list of prominent CVD graphene research activities

- A list of all CVD graphene developers and their products

- Datasheets and brochures from over 10 different CVD graphene makers

- Free updates for a year

This CVD Graphene market report provides a great introduction to CVD graphene materials and applications, and covers everything you need to know about graphene produced by CVD. This is a great guide for anyone interested in applying CVD graphene in their products, or learning more about this promising new technology.

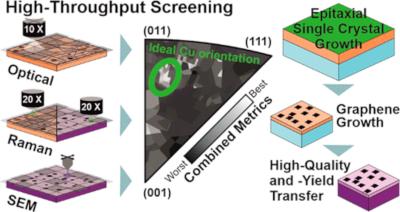

Researchers develop method for optimizing both the growth and the transfer process of graphene

A team of researchers from the University of Cambridge, RWTH Aachen University and the National Institute for Materials Science in Japan has developed a methodology for simultaneously optimizing the growth and the transfer process of graphene, showing that it is possible to dry-transfer graphene with high-yield, if the crystallographic orientation of the growth surface is chosen appropriately.

Graphene often needs to be transferred from the growth substrate (typically copper) to a final substrate where components can be built. However, current transfer approaches either lead to a substantial degradation of the crystal quality or are not compatible with high-volume manufacturing. Moreover, while graphene has great potential for next generation electronics, the gap between the performance of “hero devices” realized in research labs and what can be reproducibly fabricated with scalable approaches remains large. This is why high-end electronic devices enabled by graphene are still not on the market – and why scalability is such a challenge in terms of making the most of this nanomaterial.

Pagination

- Page 1

- Next page