Reduced graphene oxide: an introduction

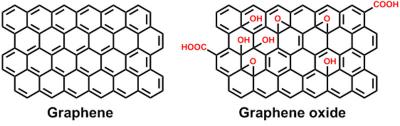

Graphene, a 2D sheet of carbon atoms arranged in a chicken wire pattern, is a fascinating material that boasts many exciting properties like mechanical strength, thermal and electrical conductivity, intriguing optical properties and more. Graphene is the focus of vigorous R&D, but its relatively high price is a hindrance at the moment.

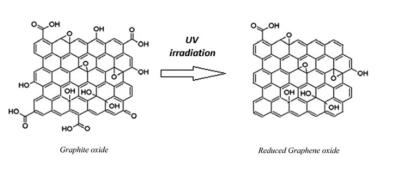

Graphene oxide is a form of graphene that includes oxygen functional groups, and has interesting properties that can be different than those of graphene. By reducing graphene oxide, these oxidized functional groups are removed, to obtain a graphene material. This graphene material is called reduced graphene oxide, often abbreviated to rGO. rGO can also be obtained from graphite oxide, a material made of many layers of graphene oxide, after a series of reduction to graphene oxide and then to rGO.

How is rGO produced?

Since effective yet inexpensive ways to make graphene (or closely related materials, such as rGO) are being intensively sought for, the reduction of graphene oxide (or graphite oxide) to rGO is popular and attractive. Several methods of reduction into rGO exist, and are rather cost-efficient and simple.

While rGO is indeed a form of graphene with properties similar to that of graphene (good conductive properties etc.), rGO usually contains more defects and is of lesser quality than graphene produced directly from graphite. Reduced graphene oxide (rGO) contains residual oxygen and other heteroatoms, as well as structural defects. Despite rGO’s less-than-perfect resemblance to pristine graphene, it is still an appealing material that can definitely be sufficient in quality for various applications, but for more attractive pricing and manufacturing processes. Reduced graphene oxide can be used (depending on the specific material’s quality) for the same various applications suitable for graphene use, like composite materials, conductive inks, sensors and more.

Reduced GO is often a natural and understandable choice for applications that call for large amounts of material due to the relative ease in creating sufficient quantities of graphene in a relatively low cost.

The process of reducing graphene oxide to produce reduced graphene oxide is extremely important as it has a large impact on the quality of the rGO produced, and therefore will determine how close rGO will come, in terms of structure and properties, to pristine graphene.

A number of processes exist for the reduction of GO, based on chemical, thermal or electrochemical approaches. Some of these techniques are able to produce very high quality rGO, similar to high-quality graphene, but can be complex, expensive or time consuming to carry out.

Once reduced graphene oxide has been produced, there are ways to functionalize the material for specific use in different applications. By treating rGO with various chemicals or by creating new compounds by combining rGO with other two-dimensional materials, it’s possible to enhance the properties of the compound to suit commercial applications.

In some applications, the reduction of the GO to rGO is performed as part of the device manufacturing process. For example, a process could start with GO, mix it with a material to create a composite, and reduce the GO into rGO as part of the composite creation process or afterwards.

rGO Applications

In general, it can be said that rGO is suitable for the same sorts of applications as graphene, as the properties of these materials are similar, albeit normally less impressive at the rGO end. As was said before, the properties of rGO can vary depending on the method of preparation and the resulting morphology and chemistry of the specific rGO.

Reduced GO can be used for many applications, among these are: energy storage, composite materials, field effect transistors and more.

Interested in buying rGO? Click here for various materials and options

Researchers 3D print unique graphene frameworks for enhanced EMI shielding

Researchers from China's Nanjing University of Science and Technology and Chinese Academy of Sciences (CAS) have developed lightweight and structurally controllable 3D reduced graphene oxide frameworks decorated with magnetic components (MRGO frameworks) via 3D printing technology to tailor EMI shielding properties.

The team explains that by adjusting the preparation conditions of the MRGO frameworks, such as inter-filament spacing, composition, and pyrolysis temperature, the graphitization degree and transmission paths are influenced, enabling electrical conductivity and magnetic property, and ensuring excellent EMI shielding performance.

Researchers develop method to create stretchable and tough graphene films

Researchers have been working on creating elastic and tough graphene films, but it has proven quite challenging so far. Now, researchers at Shanghai Jiao Tong University have introduced a method to overcome this hurdle: they linked graphene nanolayers via "extendable" bridging structures.

Image credit: Angewandte Chemie

The special properties of graphene nanolayers often drop off when the layers are assembled into foils, because they are only held together by relatively weak interactions—primarily hydrogen bonds. Approaches that attempt to improve the mechanical properties of graphene foils by introducing stronger interactions have only been partially successful, leaving room for improvement in the stretchability and toughness of the materials. The research team, led by Xuzhou Yan at Shanghai Jiao Tong University in China, chose a new approach: they cross-linked graphene nanolayers with mechanically interlocked molecules whose building blocks are not chemically linked, but rather inseparably spatially entangled. The researchers used rotaxanes as their links.

Researchers develop rGO-enhanced structural supercapacitors

Researchers from the University of California San Diego and the University of Southern Mississippi recently designed a graphene-enhanced structural supercapacitor. Structural supercapacitors hold promise to expand the energy capacity of a system by integrating load-bearing and energy-storage functions in a multifunctional structure, resulting in weight savings and safety improvements.

As a proof of concept, the researchers used their structural supercapacitor to build a miniature solar-powered boat. The supercapacitor was molded to form the boat’s hull and then fitted with a small motor and circuit. The circuit was connected to a solar cell. When exposed to sunlight, the solar cell charges the supercapacitor, which in turn powers the boat’s motor. In tests, the boat was able to cruise across the water, demonstrating the efficacy of this innovative energy storage solution.

Researchers design rGO-based nerve gas sensor using human scent receptors

Researchers from Seoul National University and Samsung Electronics have developed a sensitive and selective nerve gas sensor using human scent receptors. It reliably detected a substitute for deadly sarin gas in simulated tests.

Nerve gases are often very potent, requiring highly sensitive sensors to detect them quickly and accurately. One method of boosting sensitivity combines human scent receptors with nanomaterials such as reduced graphene oxide to create a "bioelectronic nose." But since these nerve gases are still highly dangerous even in laboratory settings, many scientists rely on safer, substitute molecules instead. In the case of the sarin or soman nerve agents, dimethyl methylphosphonate (DMMP) is a common replacement. Previously, the receptor protein hOR2T7 has been used to detect DMMP, but it could only do so when the nerve agent substitute was in a liquid form, rather than as a gas. So, the research team wanted to design a "nose" of their own that was both highly sensitive and selective for the gaseous form, using nanodiscs containing the hOR2T7 receptor.

Researchers develop rGO-based approach to address oil-water separation challenges

Researchers from Qatar University (QU), Maimoona Mohamed and Nada Yahya Deyab, along with their supervisor Dr. Shabi Abbas Zaidi, have made progress in addressing the challenge of oil-water separation.

Their research focuses on developing a novel material for efficient oil recovery from oil-water mixtures. By modifying polyurethane (PU) sponges and cotton with reduced graphene oxide (rGO), they have achieved promising results in terms of hydrophobicity, oil-absorption efficacy, reusability, and cost-effectiveness, offering a promising solution to address the issue of water and soil pollution caused by oil spills.

Graphene-Info updates its Graphene Oxide Market Report

Today we published a new edition of our Graphene Oxide Market Report, with all the latest information, including both new research activities. Our market report is a comprehensive guide to graphene oxide (and r-GO) materials and their promising applications in energy storage, composite materials, bio-medical, water treatment and more.

Reading this report, you'll learn all about:

- The difference between graphene oxide and graphene

- Graphene oxide properties

- Possible applications for graphene oxide

- Reduction of graphene oxide to r-GO

The report package also provides:

- A list of prominent GO research activities

- A list of all graphene oxide developers and their products

- Datasheets for over 20 different GO materials

- Free updates for a year

This Graphene Oxide market report provides a great introduction to graphene oxide materials and applications, and covers everything you need to know about GO materials on the market. This is a great guide for anyone interested in applying graphene oxide in their products.

LayerOne and SINTEF collaborate on graphene-based conductive inks project

LayerOne (formerly Abalonyx) and SINTEF (a Norway-based research institute) have secured funding from The Norwegian Research Council for the development of innovative, scalable and sustainable conductive inks based on reduced graphene oxide (rGO). The rGO-based inks promise improved electrical conductivity and stability surpassing traditional carbon-based inks and offering a less toxic and more cost-effective alternative to metal-based inks.

The research project is a result of LayerOne’s recent breakthrough in developing a new grade of rGO with an electrical conductivity two orders of magnitude greater than standard rGO grades. In the project, LayerOne will supply the advanced rGO materials while SINTEF will leverage and build on its experience from recently concluded projects on printed electronics to develop the new conductive inks.

HydroGraph signs LOI for a graphene-batteries project with CGT and LOLC

HydroGraph Clean Power, manufacturer of graphene and other nanomaterials, has announced a letter of intent (LOI) to form a partnership with Ceylon Graphene Technologies (CGT) via LOLC Advanced Technologies (LOLC AT), which owns a majority share of CGT through a joint venture with Sri Lanka Institute of Nanotechnology (SLINTEC).

The partnership will center around a novel composite graphene blend that is said to improve the charge acceptance of lead acid batteries by 47%. HydroGraph and LOLC AT agreed to commercialize this product and pursue the lead acid battery market, projected to be worth more than $47 billion by 2030, driven in part by electric vehicle dependency on the product.

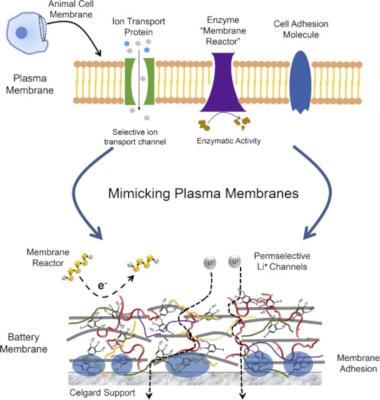

Researchers create cell plasma inspired rGO membranes for LiS batteries

Researchers from Australia's Monash University and CSIRO Manufacturing have designed a permselective membrane based on reduced graphene oxide (rGO) for making practical lithium-sulfur batteries.

The membrane closely mimics a cell plasma membrane, demonstrating selective Li+ transport and the ability to not only retain polysulfides, but also 're-activate' them on the membrane's electrochemically active interface. The team used the membrane to demonstrate high loading and high rate Li-S batteries, also on a pouch cell level.

Researchers develop rGO-based material for improved Li-S batteries

Researchers at South China Normal University, Soochow University, Nanjing Tech University and Macau University of Science and Technology have reported a new difunctional Li-S battery separator (CC-rGO/AB/PP) derived from a novel synthesis method under extreme pressure to promote more efficient Li-S batteries in a simple way.

Lithium-sulfur (Li-S) batteries theoretically have energy capacity far beyond lithium-ion batteries and have thus attracted much attention. However, the actual lifespan and conversion efficiency are significantly reduced by the shuttle effect in which lithium polysulfides (LiPSs) dissolve and penetrate to the anode during discharge and cause internal short-circuit. Although there are techniques to suppress the shuttle effect by the separator, most of them still have to sacrifice other performance indicators, such as the ability of lithium-ion transportation.

Pagination

- Page 1

- Next page