What is a coating?

A coating is a covering that is applied to the surface of an object. The purpose of applying the coating may be decorative, functional, or both. Coatings are ubiquitous and can be found on walls, furniture, on all sorts of wires and printed circuits, the outside of houses and cars, and much more. In addition, the decorative duties of coatings span quite a broad spectrum.

Decorative coatings are mainly used for their color, texture or other visual property. Functional coatings are applied to change the surface properties of the substrate, such as adhesion, wettability, corrosion resistance, wear resistance and more. In some cases, the coating adds an entirely new property such as a magnetic response or electrical conductivity and forms an essential part of the finished product.

Coatings may be used in various processes, that are roughly divided into: vapor deposition, spraying, chemical and electrochemical techniques, roll-to-roll coating processes and other, less prominent techniques.

What is graphene?

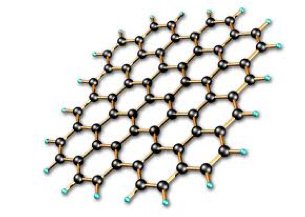

Graphene is a two dimensional layer of carbon atoms, arranged in the form of a honeycomb lattice. It is touted as a âmiracle materialâ because it is endowed with an abundance of astonishing traits - this thin, one atom thick substance is the lightest, strongest, thinnest material known to man, as well as the best heat and electricity conductor ever discovered - and the list does not end there. Graphene is the subject of relentless research and is thought to be able to revolutionize whole industries, as researchers work on many different kinds of graphene-based materials - each one with unique qualities and purpose.

Graphene for coatings

The vast selection of extraordinary properties that graphene possesses can open the door to many interesting types of coatings, paints, inks and more. Graphene's high resistivity can make for durable coatings that do not crack and are resistant to water and oil; its excellent electrical and thermal conductivity can be used to make various conductive paints, and a strong barrier effect can contribute to extraordinary anti-oxidant, scratch-resistant and anti-UVA coatings.

Graphene enables a wide array of functional coatings and paints, for many possible applications. Among these can be high performance adhesives enabled by graphene's high adhesion property, anti-bacterial coatings, solar paints (capable of absorbing solar energy and transmitting it), paints that provide isolation for houses, anti-rust coatings, anti-fog paints and UV ray blockers, non-stick coatings for various domestic applications (like frying pans and countertops) and even a much-hyped possibility (currently under scientific examination) of a coating that turns a regular wall into a screen.

Commercial activity

Graphene-enhanced products are yet to reach widespread commercialization. Nonetheless, given grapheneâs impressive array of properties and the vigorous R&D that is taking place, graphene-enhanced coatings should not be too far away.

The Sixth Element Materials, a Chinese company that focuses on R&D, mass production and sales of graphene and related materials, showcased its graphene-zinc anti-corrosion primer used for offshore wind power tower, that can come at a competitive price compared with zinc rich epoxy primer.

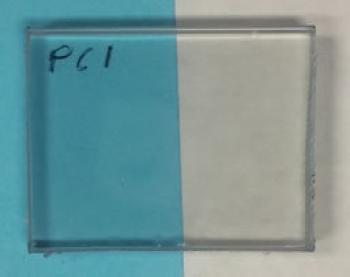

Garmor, the University of Central Florida spin-off formed to develop a new graphene oxide flakes production process, has developed graphene oxide-based coatings useful for limiting UV radiation damage to sensors and polymers. Garmor's transparent GO-films are reportedly derived from a commercially-viable and scalable process that can be readily implemented with minimal constraints.

Four layers of GO coating on polycarbonate

Four layers of GO coating on polycarbonate

The Spain-based Graphenano announced the launch of a graphene-based series of paints and coatings called Graphenstone in 2014. These are said to be very strong and also acts as a protective layer against environmental damage. Graphenstone is made from a graphene powder and limestone powder.

The British Electro Conductive Products released a sprayable transparent conductive coating based on a CNT and graphene platelets (GNP) hybrid material. TBA are targeting the food, electronics, pharmaceuticals and petrochemicals markets.The new ATEX-compliant product is available as a clear, anti-static aerosol, and it should also be available as bulk paint. Its application will safeguard electronic equipment used in explosive environments and bring it up to European standards.