A new super-elastic 3D graphene excite researchers

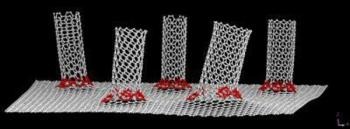

Researchers from Monash University (Australia) have managed to grow 3D graphene "towers" that make graphene more elastic. The new 3D material supports 50,000 times its own weight, springs back into shape after being compressed by up to 80% and has a very low density. The material still retains graphene's conductivity.

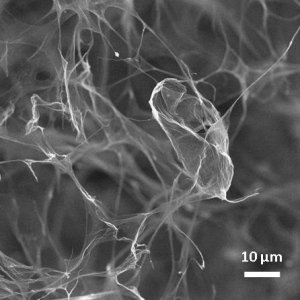

To develop the new material, the researchers used ice crystal as templates to grow the graphene towers from graphene oxide flakes. The technique was adapted from freeze casting which involves growing layers of soluble graphene oxide between forming ice crystals. By partially stripping the oxygen coating before freeze casting, they could enhance the bonding between adjacent flakes in the network, producing much stronger materials then before. The individual graphene sheets are neatly aligned, forming an ordered network of hexagonal pores.