Researchers' new approach could boost graphene’s energy and computing prospects

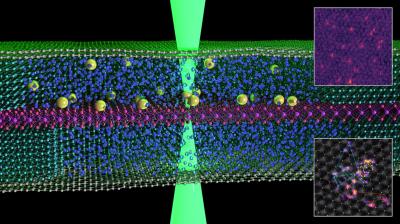

Researchers at the National Graphene Institute and their collaborators have gained understanding into how electric field effects can selectively accelerate coupled electrochemical processes in graphene. Electrochemical processes are essential in renewable energy technologies like batteries, fuel cells, and electrolysers. However, their efficiency is often hindered by slow reactions and unwanted side effects. Traditional approaches have focused on new materials, yet significant challenges remain.

The Manchester team, led by Dr. Marcelo Lozada-Hidalgo, has taken a novel approach. They have successfully decoupled the inseparable link between charge and electric field within graphene electrodes, enabling unprecedented control over electrochemical processes in this material. The breakthrough challenges previous assumptions and opens new avenues for energy technologies.