The latest graphene ink news:

Researchers develop improved graphene micro supercapacitors for wearables

Researchers from China University of Petroleum (East China), Henan Agricultural University and Chinese Academy of Sciences have developed an additive-free 3D printing process to construct graphene micro-supercapacitors (MSCs) with unprecedented electrochemical properties and seamless integrability. The team states that this achievement overcomes existing manufacturing limitations and brings closer the on-chip MSC arrays essential for the next generation of wearables.

Wearable devices require ever-smaller on-board energy solutions that can deliver bursts of power while remaining unobtrusive. Rigid coin batteries restrict device flexibility and ergonomics. Leading microscale alternatives include micro-supercapacitors (MSCs), which store and discharge energy rapidly owing to highly porous electrode materials interfacing with electrolytes. Supercapacitors’ quick charge ability and resilience to repeated charging cycles make them appealing to supplement batteries. However, difficulties producing intricately designed MSC devices that also offer high performance have confined MSCs to the lab. Conventional manufacturing techniques often lack suitable precision, flexibility, and scalability.

Versarien's turnaround strategy to benefit from Gnanomat's new funding

Versarien has reported that its Spanish business has secured funding for a new project, in a boost to the group’s turnaround strategy. The Company said its majority-owned subsidiary, Gnanomat, has been awarded a grant of around €415,000 (around USD$445,660) by a government body.

Gnanomat will use the money to help develop and commercialize a new line of conductive inks based on Versarien's nanomaterials, for use in the production of electronic goods.

Haydale announces new contract with Cadent for graphene ink-based low-power radiator heaters

Haydale has announced its next collaboration with Cadent, to develop graphene ink-based low-power radiator heaters. The £350,000 three-stage project will run for 12-months and is aiming to develop a tested and validated market-ready product as a cost-effective alternative for Cadent's customers when their gas supply is interrupted.

Following continued success on the low-power, battery operated water heating development, the aim for the latest project is to incorporate the same graphene-ink based technology into different designs to deliver bespoke solutions for a wide range of customer requirements.

Researchers develop "e-skin" from graphene and seaweed microcapsules

Researchers at Queen Mary University, University of Sussex and University of Brighton have integrated graphene into seaweed to create nanocomposite microcapsules for highly tunable and sustainable epidermal electronics. When assembled into networks, the tiny capsules can record muscular, breathing, pulse, and blood pressure measurements in real-time with ultrahigh precision.

The team explained that much of the current research on nanocomposite-based sensors is related to non-sustainable materials. This means that these devices contribute to plastic waste when they are no longer in use. The new study shows that it is possible to combine molecular gastronomy concepts with biodegradable materials to create such devices that are not only environmentally friendly, but also have the potential to outperform the non-sustainable ones.

Haydale awarded SMART funding to bring graphene products to market

Haydale has announced that it has been awarded SMART Flexible Innovation Support ("SMART FIS") from The Welsh Government to accelerate the development of its graphene underfloor heating product and range of biomedical sensor inks.

As part of a new innovation strategy for Wales, aimed at supporting Welsh industry by increased investment in research, development, and innovation, SMART FIS will provide Haydale with funding totaling £182,843 over a two-year period. Part of this funding will enable Haydale to accelerate the development of its prototype graphene underfloor heating ("UFH") towards a market-ready CE product that can be tested in a home environment. It will support continued engagement with partners such as City Energy Network Ltd and Plumbase.

LayerOne and SINTEF collaborate on graphene-based conductive inks project

LayerOne (formerly Abalonyx) and SINTEF (a Norway-based research institute) have secured funding from The Norwegian Research Council for the development of innovative, scalable and sustainable conductive inks based on reduced graphene oxide (rGO). The rGO-based inks promise improved electrical conductivity and stability surpassing traditional carbon-based inks and offering a less toxic and more cost-effective alternative to metal-based inks.

The research project is a result of LayerOne’s recent breakthrough in developing a new grade of rGO with an electrical conductivity two orders of magnitude greater than standard rGO grades. In the project, LayerOne will supply the advanced rGO materials while SINTEF will leverage and build on its experience from recently concluded projects on printed electronics to develop the new conductive inks.

Researchers develop a sprayable graphene biosensing platform for rapid and low-cost chemical sensing

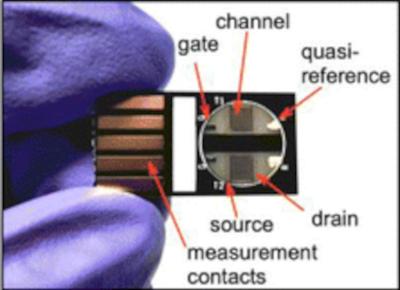

Scientists from Imperial College London and Catania University & CNR-IMM have developed a novel graphene ink that can be used to detect a variety of chemical substances when layered on top of commercially available printed circuit boards (PCBs) as a thin film.

In their recent paper, the team demonstrated a novel and versatile sensing platform, based on electrolyte-gated graphene field-effect transistors, for easy, low-cost and scalable production of chemical sensor test strips. The Lab-on-PCB platform is enabled by low-boiling, low-surface-tension sprayable graphene ink deposited on a substrate manufactured using a commercial printed circuit board process.

Haydale and City Energy develop graphene underfloor heating with Plumbase

Haydale has announced it is working with City Energy Network Limited and Plumbase Limited on developing and distributing its graphene underfloor heating ("UFH").

The ink heater technology applied to clothing worn by British athletes at the Tokyo Games has been applied in an initial prototype for domestic UFH with the potential to replace gas central heating and link into other energy efficient technologies.

Versarien announces launch of Umbro's ProTraining Elite range incorporating its graphene technology

Versarien has announced the launch of Umbro's ProTraining Elite range, including garments incorporating the Company's Graphene-Wear technology.

Versarien has been working with Umbro since 2018 and these are the first products to be launched in Europe incorporating the Company's technology. Umbro's new ProTraining Elite long-sleeve running tops, baselayers and running tights have Versarien's Graphene-Wear ink formula printed on the inside. The Graphene-Wear formula features novel properties that will allow wearers to experience enhanced thermal transmittance, increased moisture management, with improved drying rate, without compromising air or water vapor permeability. In particular, these three garments will benefit significantly from applying Graphene-Wear as they are being worn in circumstances where maintaining core body temperature is more desirable and difficult to achieve. The garments also have Versarien's Graphene-Wear trademark applied.

Haydale reports its financial results for H1 FY2023

UK-based graphene developer Haydale announced its unaudited interim results for the six months ended 31 December 2022 (H1 FY2023). Revenues were £1.78 million (up 50% from H1 FY2022), and operating loss was £1.89 million (up from £1.75 million in 2022). At the end of the year, Haydale had £2.97 million, following a successful fund raise of £5.14 million in September 2022.

The updates that it is starting to sell its biomedical inks in Europe, with advanced trials being conducted by several parties which include electronic blood glucose reader compatibility tests.

Pagination

- Page 1

- Next page