KAIST team develops a fast and powerful graphene-based aqueous hybrid capacitor that may lead to a new type of energy storage system

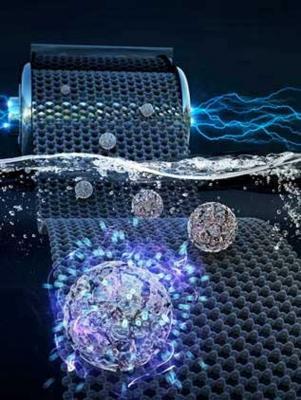

A KAIST research team has developed a graphene-based hybrid storage device with power density 100 times faster than conventional batteries, allowing it to be charged within a few seconds. The team states that it could be suitable for small portable electronic devices.

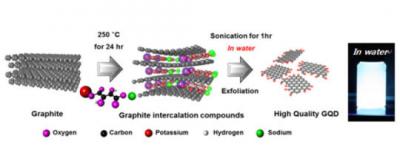

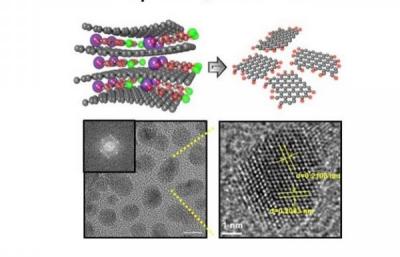

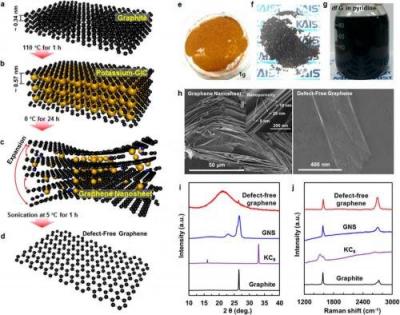

Porous metal oxide nanoparticles formed on graphene in the aqueous hybrid capacitor. (Image: KAIST)

Porous metal oxide nanoparticles formed on graphene in the aqueous hybrid capacitor. (Image: KAIST)

The researchers developed an aqueous hybrid capacitor (AHC) that boasts high energy density, high power, and excellent cycle stability by synthesizing two types of porous metal oxide nanoclusters on graphene to create positive and negative electrodes for AHCs.